APOLLON

Automatic Visual Inspection

- TRAY BASED INSPECTION

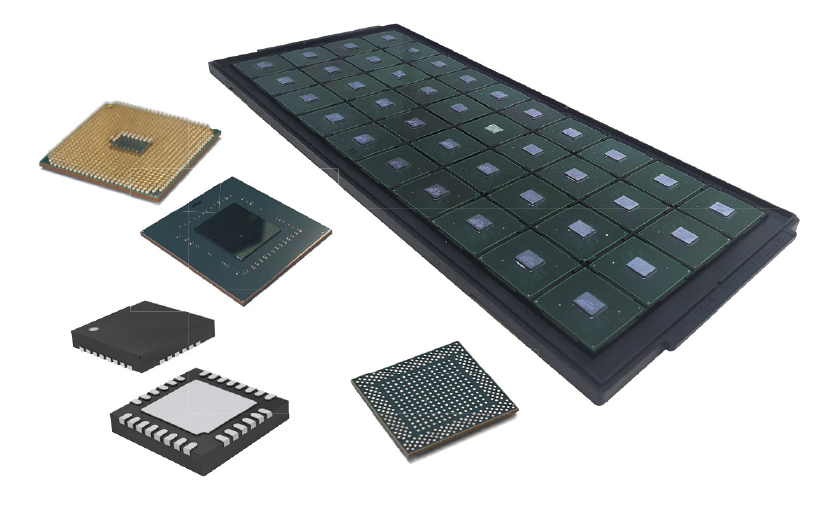

It accommodates a variety of package handled by the tray such as BGA,LGA,GFN,QFP,CSP,SOP, etc - 3D double loading inspection

It does not only identify OK and NG, it also inspects double-loaded material More accurate double loading inspection is performed by 3D inspection method compared to laser method. - Accurate SPC process management system

3D image storage and NG review function without tray handling in the eequipment

影片

Vision Technologies

TRAY-BASED VISION SOLUTION

Bottom Vision Inspection

Top Vision Inspection

4Sides Vision Inspection

PACKAGE Inspection

APOLLON is a double-sided automatic vision inspection for memory composed of PEMTRON's breakthrough technology.

The APOLLON vision machine provides unprecedented inspection capability at unseen accuracy.

Reliable and Highest Accuracy

Reliable 3D inspection of all objects: ball, leads, passive devices, solder pads, etc.

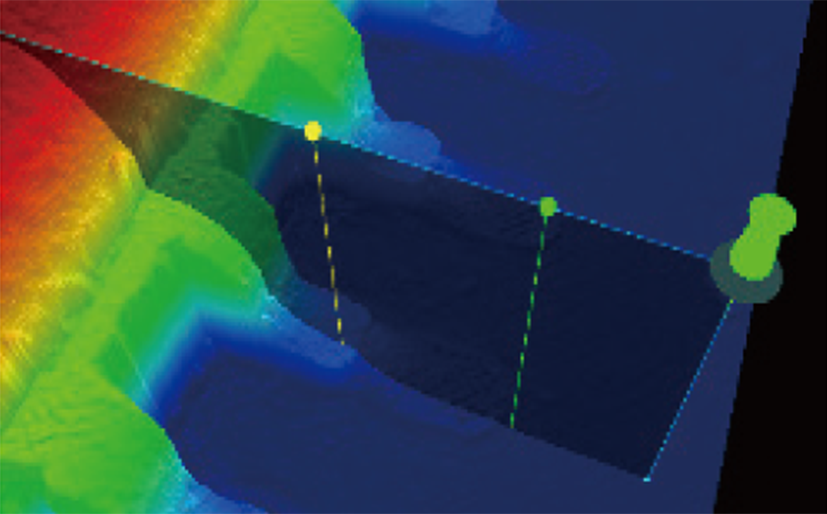

3D scan of surfaces to detect and measure dents and bulges

Reliable and accurate part height measurement

4way Side Vision Inspection

TOP/BOTTOM 5side Inspection

High speed device is available for side inspection depending on production requirements.

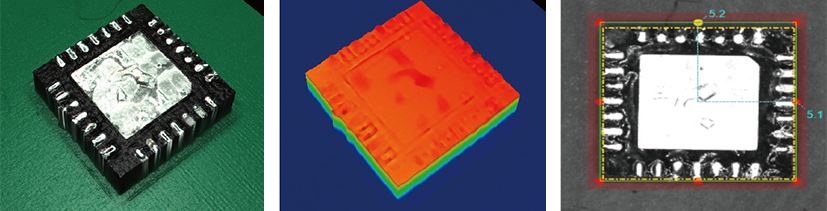

Advanced 3D + 2D Inspection

Diversification of detection types with 3D detection function

With automatic Algorithm, positive/non-determination and classification can be made on the facility

High-resolution capability

Large FOV with increased homogeneity

Color inspection to find defects like discoloration shields, exposed bond wire, plating defects, etc.

Inspection ability to detect micro cracks

Color review imaging

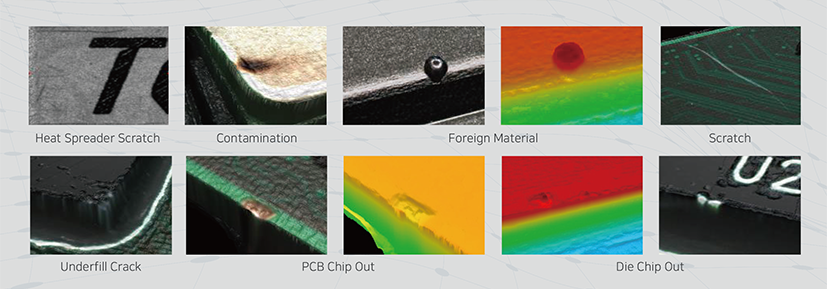

TOP VISION INSPECTION Comprehensive 3D+2D Inspection

Inspection on top surface of any packages for various marking defects.

Heat spreader Scratch and PCB surface of various packages.

Inspection on the components mounted on PCB.

Inspection on the underlying exposed metal.

BOTTOM VISION INSPECTION

Inspection for Bottom view for wide range of package such as QFP, TSOP, BGA,CSP, and Side Inspection for leadless devices

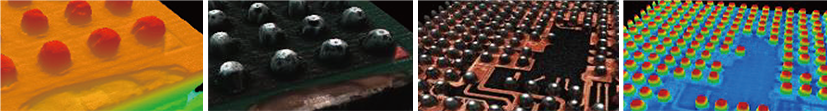

BGA Package Inspection

Warpage, Ball Height, Coplanarity, Offset, Ball Width, Ball Quallity, Grid-to-Package Offset, Pitch, Contrast, Body Width Height, Ball Presence/Absence, Component Height

Leadless Packages Inspection

Position, Pitch, Width, Length, Pad Spacing, Distance to Edge, Edge Straightness

Body width/Body Height, Edge Parallelism, Edge Orthogonality, Edge Parallelism/Orthogonality

Leadless Packages Inspection

Lead Coplanarity, Body Standoff, Lead Offset/Skew, Lead Pitch, Lead Width, Terminal Dimension, Foot Angle, Lead Sweep.

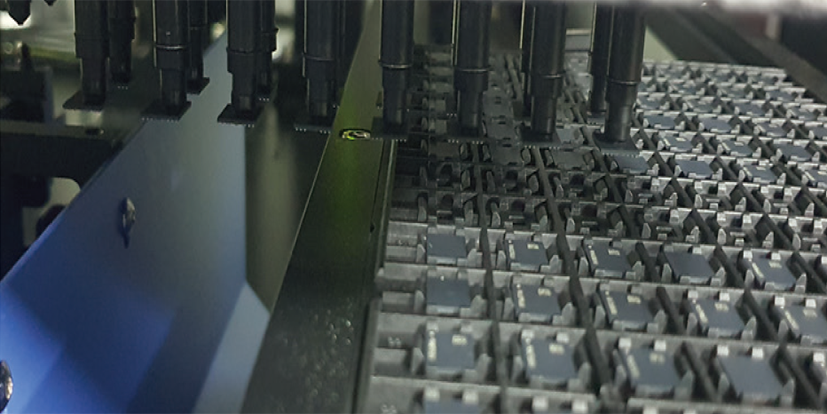

TRAY BASED INSPECTION

It accommodates a variety of package handled by the tray such as BGA,LGA,GFN,QFP,CSP,SOP, etc

High-speed inspection

Convenience for workers

Automatic sorting, re-inspection function. fast conversion time

3D double loading inspection

It does not only identify OK and NG, it also inspects double-loaded material

More accurate double loading inspection is performed by 3D inspection method compared to laser method.

Accurate SPC process management system

3D image storage and NG review function without tray handling in the equipment.

Capable of management of various statistical process data with basis of Accurate measurement

result extracted by SPC.

Defects can be confirmed through defect history,

image confirmation and It is possible to track and map the location of the badly sorted

JEDEC tray from the SPC data.

Increasing production yield rate.

checking process status check,

Identifying cause of defect

Product quality improvement,

At-a-glance interface for Operator

Data collection in Real time,

3D NG Image save &NG Review