KIC RPI

Reflow Process Inspection

for a transparent reflow process

- Process Traceability for each PCB

- Management Data for Reflow Quality and Throughput

- Reduced Production Costs

- Temperature Profile Data for Every PCB

- Automated Continuous Profiling

- Meets Medical Device ISO 13485

- Compatible with Select Vacuum Reflow Ovens

- KIC RPI datasheet

- KIC RPI A4 size datasheet

Managing the Ultimate Reflow Oven Process Output

A reflow oven is a very busy machine striving to control multiple variables while heating and cooling PCBs. The purpose of the oven, however, is very simple.

- To create a specific PCB profile

- To maintain a required throughput

video

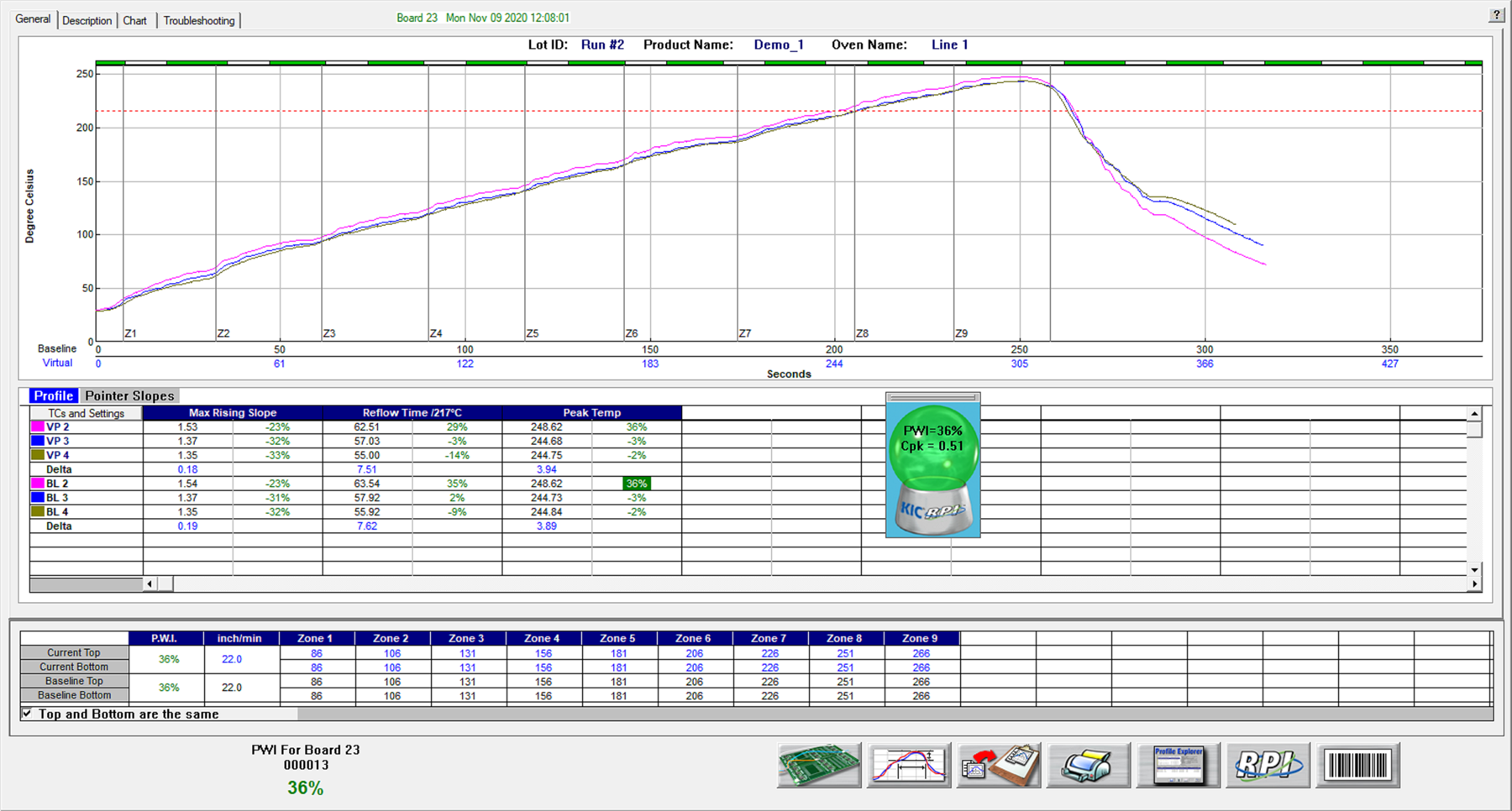

PCB Profile Traceability

The RPI utilizes embedded sensors for heat and conveyor speed to automatically measure and display the following information:

- PCB profile

- Profile’s “fit” to the process window

- Continuously displayed production details

‧#PCBs produced

‧Product name and lot ID

‧Production date and time stamp

‧Oven name - PCB process traceability

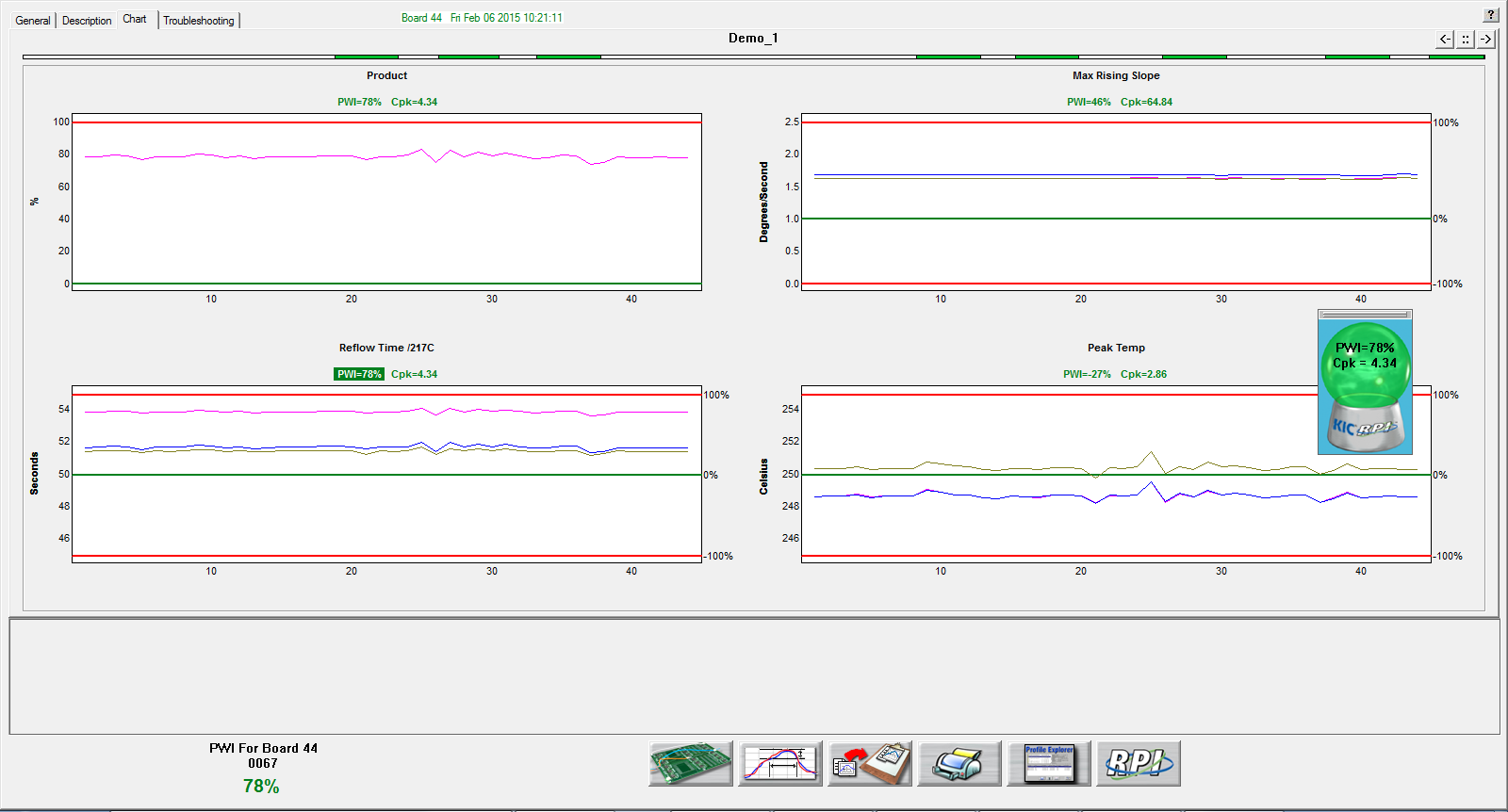

- SPC & Cpk charts

- Statistics of defects and process yields

- Pareto chart on out of spec occurrences

The RPI features include:

- Profile optimization software

- Barcode reading software

- Remote Process Monitoring software

- Alarm Relay

- Light Bar

Fail-Safe Operation

- There are numerous opportunities for mistakes and defects to occur in the reflow process. Human errors include loading the wrong oven program or loading the wrong PCBs. The RPI’s bar code capability prevents such mismatch.

- Another common defect occurs when the process drifts out of spec or out of control. The RPI will immediately alert the responsible personnel of such occurrences and can shut down the infeed conveyor if desirable.

- SPC charts will alert the engineer of upcoming trouble, typically when the reflow oven is still operating within spec.

Bottom Line

KIC’s Reflow Process Inspection System – RPI ensures a healthy profile for every board you build. Can you prove to your auditor the in-spec temperature profile for every board passing through the reflow process?

- Meet requirements for medical devices for ISO 13485

- Satisfy all of your auditor’s requirements for reliability and traceability

- Board-level traceability – reflow temperature profile data

- SPC – UCL/LCL, Cpk data and control charts in real-time

RPI System

System Components

- Two (2) thermocouple probes (each probe has 15 thermocouples)

- 1 ea. data acquisition unit

- 1 ea. speed encoder

- 1 ea. board sensor

- 1 ea. alarm relay

- 1 ea. light tower

- 1 ea. KIC RPI software with software protection dongle

Note: The RPI requires a KIC profiler

Automatic SPC Charting with Real-time Cpk

Temperature Graph and Data for Each PCB Processed

RPI Vacuum System

System Components

In addition to “standard” RPI features:

- Process monitoring capabilities throughout the entire process, including vacuum zone

- Duration in vacuum zone automatically saved for each PCB

- Dynamic graphical display of vacuum zone for each PCB

- Compatible with select* vacuum reflow ovens

Contact KIC to check for compatibility with your machine.

*Requires communication with oven controller software. May require purchase of vacuum communication package from oven manufacturer.

| Accuracy: | ± 2°F (1.2°C) |

| Readings/second: | 13 |

| Thermocouples: | Type K |

| Temperature Range: | -150°C to 450°C |

| Dimensions: | |

|---|---|

| Data acquisition unit (LxWxH): | 308.6mm x 173.5mm x 35.8mm |

| Probes: | length and thermocouple spacing is customized to each oven |

| Communications: | Ethernet, RJ-45 connector |

| Computer Capability: | PC |

| Power Requirements: | 12V DC @ 300mA |

Computer Configuration

Minimum System Requirements

- Dual Core / 1 GHz Processor PC with 2 GB RAM

- 2 GB available storage

- Video 1024 x 768 resolution / 16-bit

- 1 available USB port (for data download)

- 1 available USB port (for software key)

- 1 available Ethernet port or 1 available USB port with Ethernet to USB