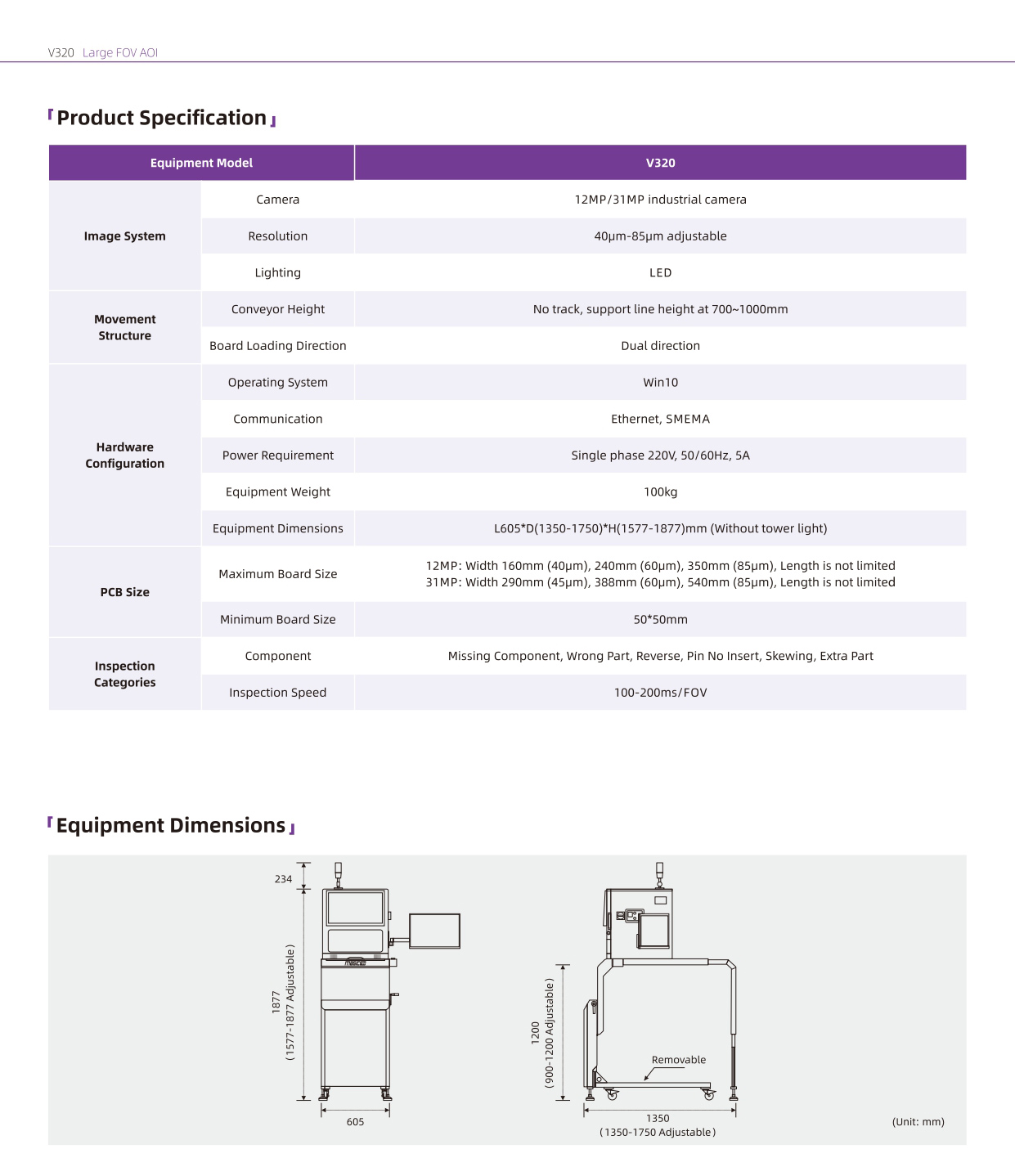

V320

Large FOV AOI

MagicRay V320 ADI is designed as a cost effective pre-wave inspection machine to root out errors caused by operators' fatigue. With low maintenance and high productivity, return-on-investment can be easily justified.

▶ Deep-learning Algorithm

▶ Color Difference Analysis Algorithm

▶ Feature-analysis Algorithm

▶ Auto Model Assignment

▶ Image Intelligent Recognition

▶ Search Detection Algorithm

Video

Function and Feature

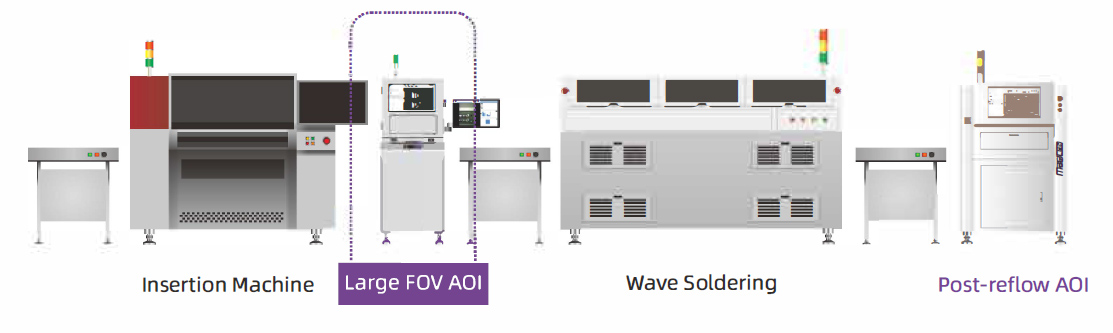

Scene shooting: Cross-track design

Pre-wave Soldering Quality Defender

It can easily be put into use in any existing production line without the need for a line re-layout.

Through the use of Al, programming is made simple. An inexperienced operator can generate a stable program within minutes.

Support high-mix products changeover and barcode identification for traceability.

The machine will trigger the voice and buzzer alarm when defect is detected and it stops entering of next board before the defect is corrected.

Structural Features

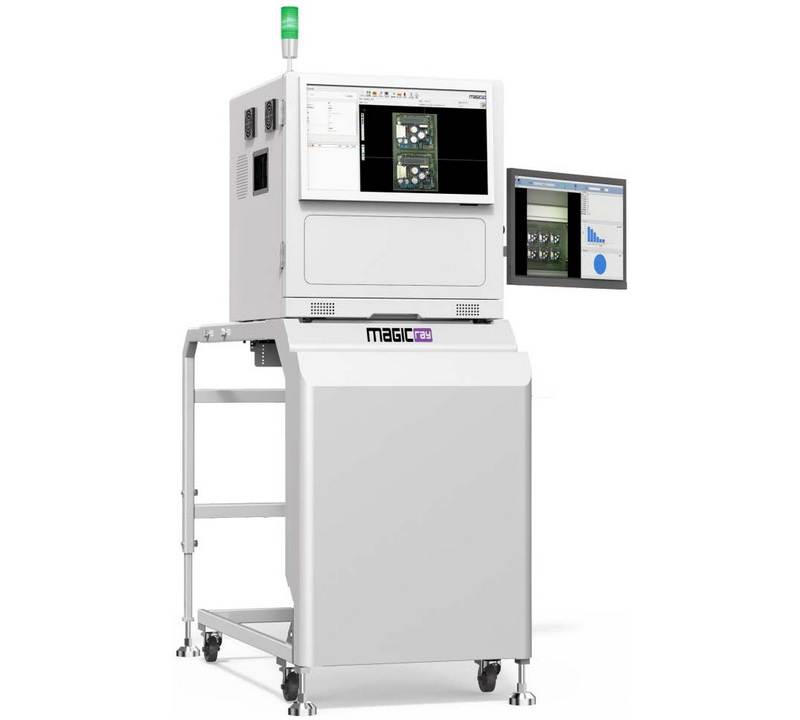

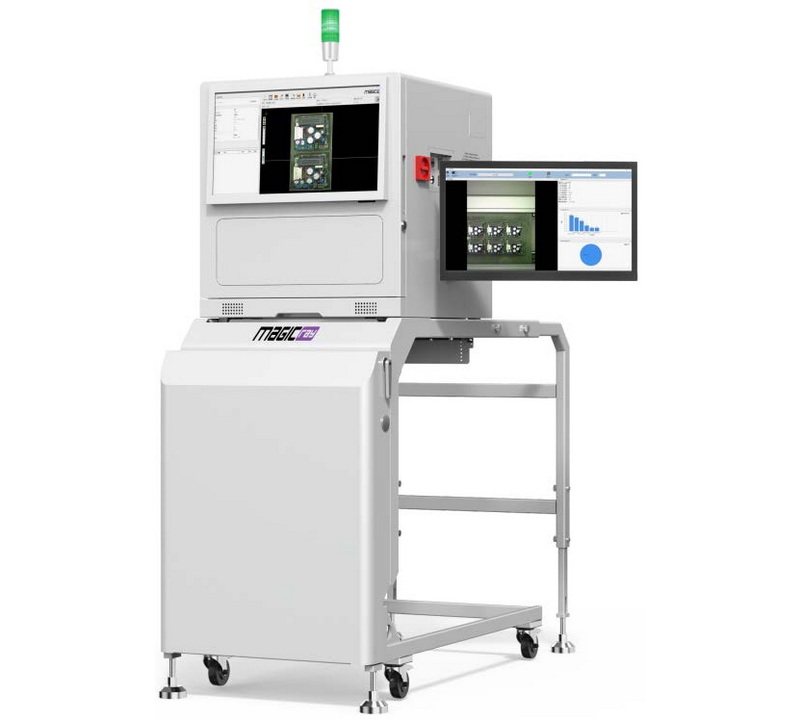

Equipped with dual monitors, programming and re-judgment can be done easily.

Multi-camera resolution option 1s available to adapt to different board sizes.

Adjustable height and depth, ensure ease of installation.

The secondary screen can be freely adjusted to adapt to the direction of flow of the production line.

Compact and cross-track design, allows ease of installation into the existing production line, without the need to increase production space.

Removable caster-wheel base provides greater flexibility of installation.

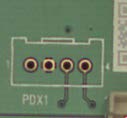

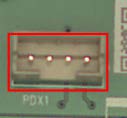

InspectionExamples

Core Technology and Advantages

Deep-learning Algorithm

Use of big data learning allows system to accurately identify component polarity and automate programming.Color Difference Analysis Algorithm

Help to analyze differences in color and brightness, effectively overcoming challenges when inspecting for partial damage or mis-hole location.Feature-analysis Algorithm

Automatically extract partial features to effectively deal with complex and changeable detection scenes.Auto Model Assignment

Automatically assign the component type to inspect defects such as missing, wrong or skewed components.Image Intelligent Recognition

Extract PCB samples which makes high-speed and non-stop inspection a reality.Search Detection Algorithm

Automatically scan for partial defects of the component in cases where the defects location is not fixed.Production Line Solution

WaveSoldering