New generation dispenser gives sophisticated SMT support along with multi-functions, high accuracy and high-speed!

- High-speed, High-accuracy and Stable Dispensing for High-density Mounting

- Non-contact Dispensing and Line Dispensing, Support for Wide Range Applications

- Support for Yamaha SMT Software and Production Line Network, Delivers Highly Efficient Production

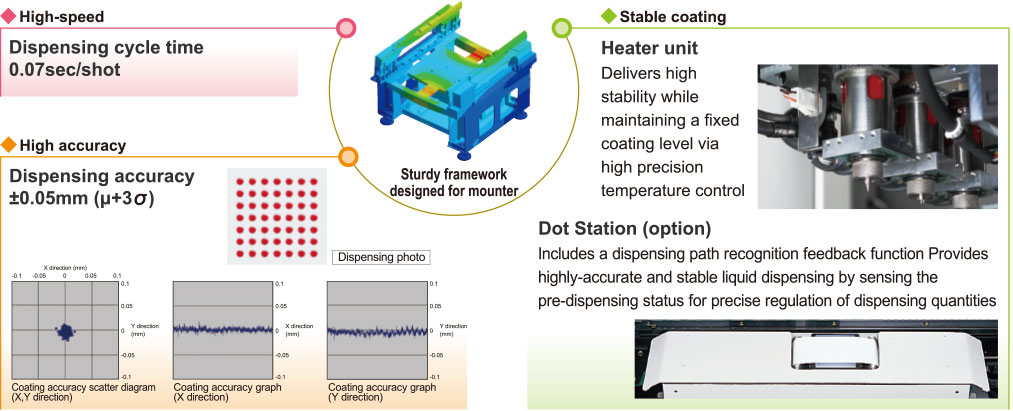

- Dispensing tact 0.07sec/shot

- Dispensing accuracy +/-0.05mm (μ+3σ)

Function and Feature

Dispensing cycle time 0.07sec/shot

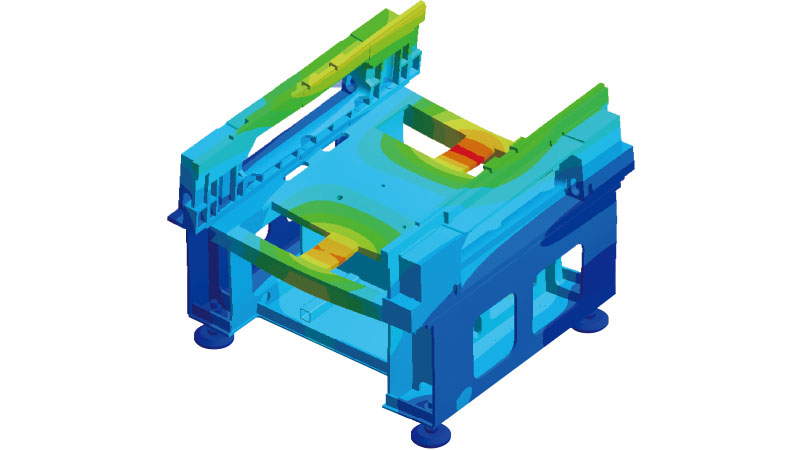

High-accuracy and Stable Dispensing

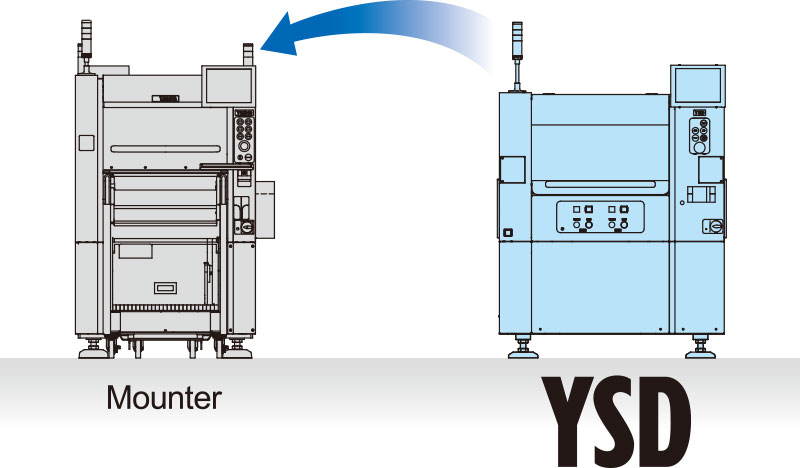

Mounter-linked operation

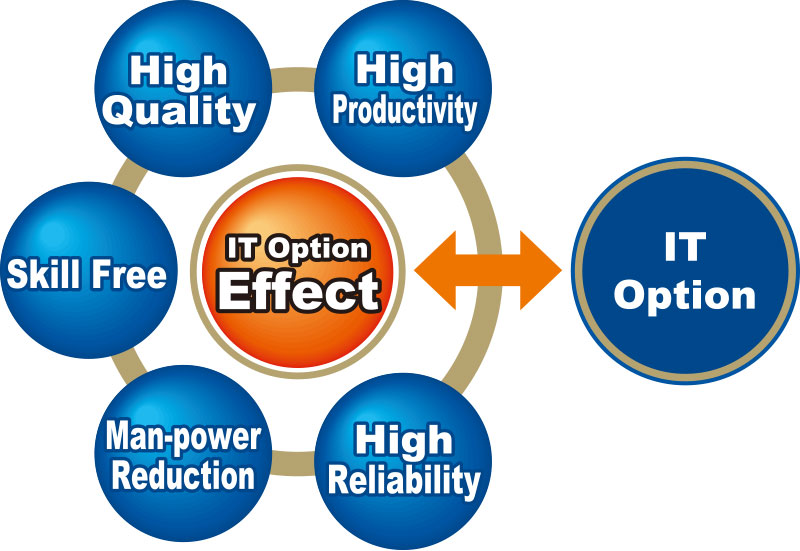

IT Option

Viedo

Feature

High-speed, High-accuracy and Stable Dispensing for High-density Mounting

Non-contact Dispensing and Line Dispensing, Support for Wide Range Applications

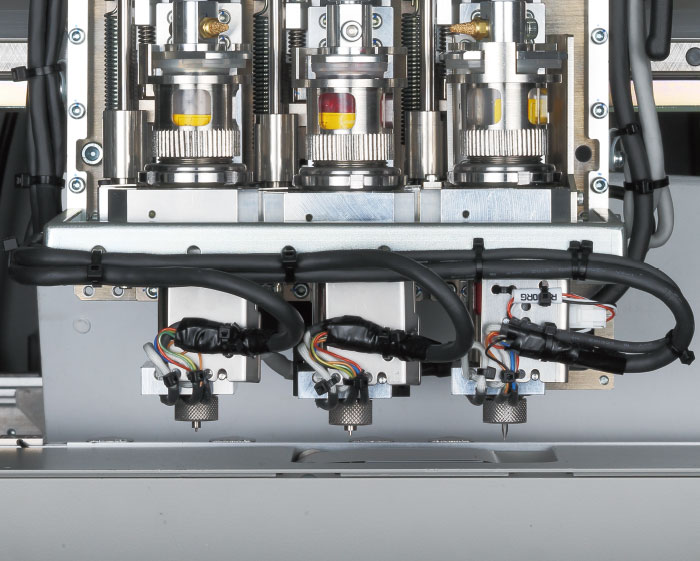

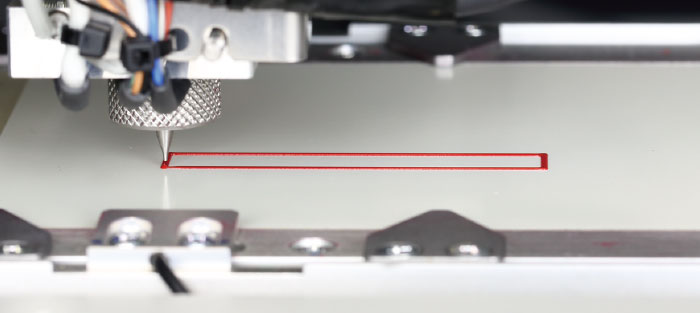

Dispense head

Select from 2 head (standard) or 3 head (option) to match the production format.

Full universal type high accuracy dispense head gives independent Z-axis & R

axis servo control, while supporting multi-fluid, multi-state liquid dispensing.

Direct syringe and nozzle mounting method simplifies maintenance tasks such as

cleaning

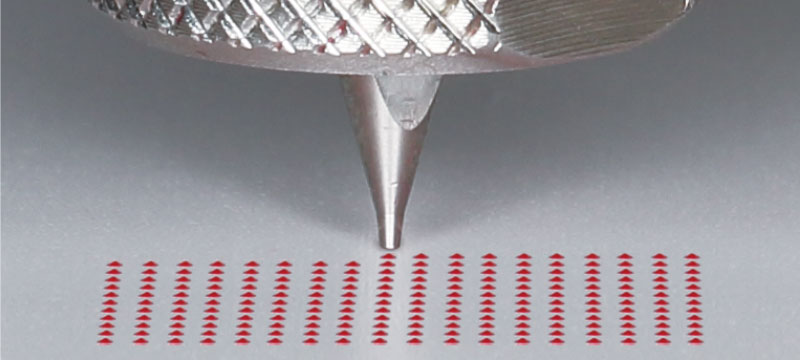

Non-contact dispensing(option)

Excellent dispensing & coating on board cavities, on already part-mounted boards and where stoppers cannot be used such as on high-density mounted boards

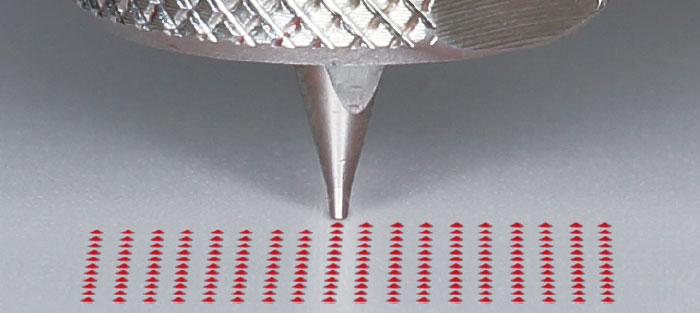

Line dispensing(option)

Dispenses fluid in line patterns to match the board shape Supports a variety of applications such as filling and insulating tasks.

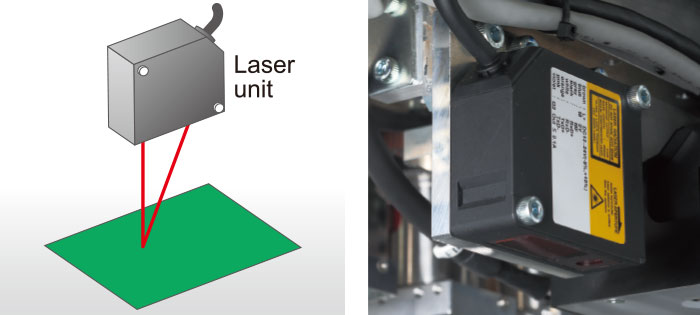

Laser unit

Laser beam detects board high and curvature, to ensure high-precision non-contact dispensing and line dispensing!

Syringe

Supports syringes in all types and capacities. Select the type you need to match your application.

Nozzle

Select a nozzle matching the dispensing pattern.

Digital pressure gauge

High-accuracy digital pressure gauge for precision dispensing

Support for Yamaha SMT Software and Production Line Network, Delivers Highly Efficient Production

Mounter-linked operation

Smoothly converts data from Yamaha mounters to dispense data. This means huge cuts in production times!

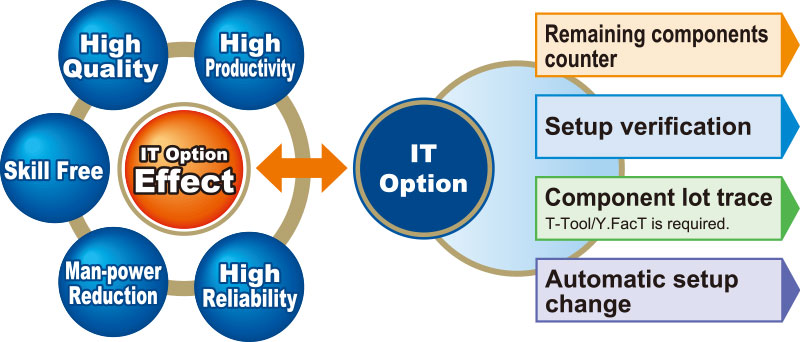

IT Option

Powerful support tool for boosting mounting line production and upgrading reliability! This development contributes to skill-free operation, low man-hours, and enhanced product quality. Vital support for online work tasks on machines.

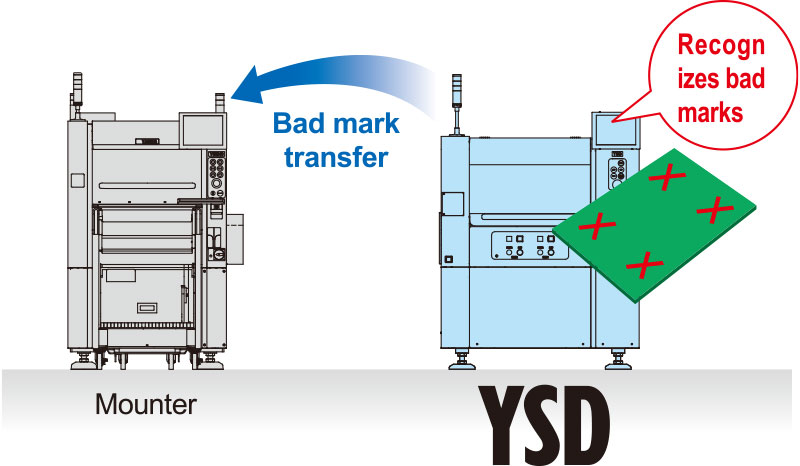

Bad mark transfer

Bad mark data recognized by the YSD is transferred to the mounter to drastically cut total line loss and boost production

Full range of options!

- Conveyor extensions

- Board transport direction

- Board transport rear reference

- Syringe level sensing

- 10cc adapter

- UPS system

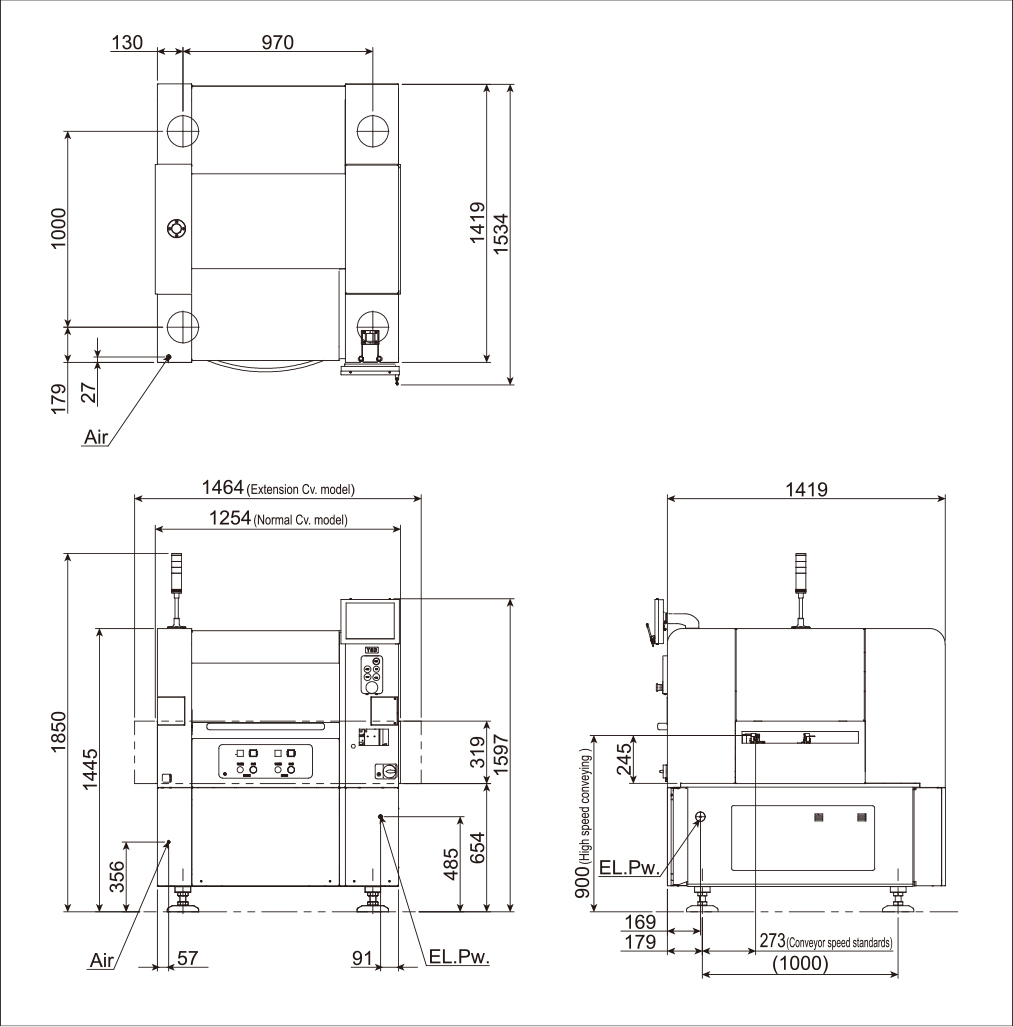

Specifications, External dimension

Specifications

| Model | YSD |

|---|---|

| Applicable PCB | L510 x W460mm~L50 x W50mm

* Please contact us for board size that exceeds the above |

| Dispensing tact | 0.07sec/shot (under optimum condition) |

| Dispensing accuracy | +/- 0.05mm (µ+3σ) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% |

| Air supply source | 0.45MPa or more |

| External dimension | L1,254 x W1,419 x H1,445mm (excluding projections) |

| Weight | Approx. 1,250kg |

Specifications and appearance are subject to change without prior notice.

External dimension