All-purpose surface mounter with the highest speed in its class brings 1head solution evolution to a whole new level!

- World’s fastest mounting speed in its class; 5% faster than the YSM20.

Featuring a new wide-scan camera with improved component adaptability. - Optional features improving line operating rate without stopping the machine

Function and Feature

Superb mounting performance 95,000 CPH (under optimum conditions as defined by Yamaha Motor)

Needs no head replacement! 0201mm to large-size components

Conveyors available in freely configurable variations

Realize non-stop components supply

Recommend for Such Production Site

For customers dealing with many PCB-component types and many changeovers

Highly flexible heads and efficient changeover operation ensure seamless high-mix production.

Capable of handling different component and PCB sizes on the same platform

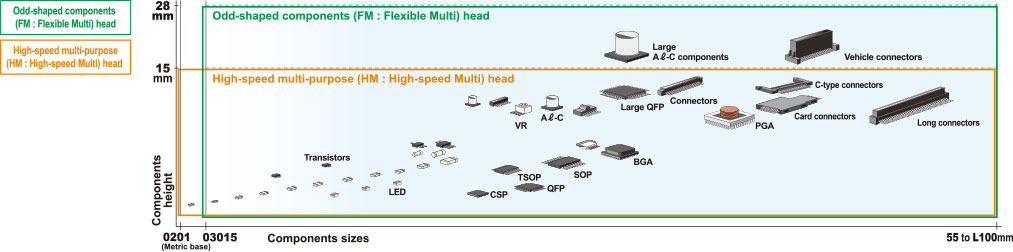

- HM head: One head handles more than 90% of component sizes (in-house research)

- FM head: is a high-precision high-efficiency head that holds up to 5 nozzles while also handling large-size-tall and odd-shaped component. The FM head also has a force control function.

- HM head: Wide scan camera that comes with the HM head recognizes components from 0201mm to 12x12mm. Realizes high productivity via linear head line-of-flow movement.

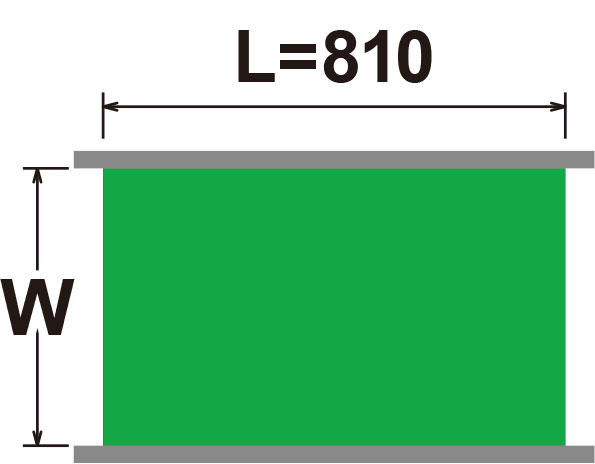

- Handles ultra large PCBs to a maximum size of L810 x W490. Dual stage mechanism ensures no wasted movement for each PCB size.

Reduces loss from line stoppages due to product changeovers to realize a "keep working" line even for high-mix production jobs.

- Holds a maximum of 140 feeder slots (fixed component table bank specification). Allows setting multiple component types in one batch.

- Using "Auto-grouping function and "Common-setup optimization function" provides maximum throughput with a minimal number of product changeovers.

- Easy operability along with using just 2 compact feeder carriages each at front and rear ensures optimal operation with minimal feeder carriage changeovers.

- Auto Programming Changeover function eliminates human worker tasks including program changes, support pin placement and other tasks.

Z:LEX supports a high degree of mounting quality through meticulous follow-up-tracing in production environments using diverse component types and by revising setup-changeovers.

- Z:LEX includes component data creation support functions as standard features to automatically generate recognition data for special shape components and automatically write recognition data for the equipment.

- Automated correction and teaching functions for pickup position and pickup height ensure stable and accurate component pickups.

- Self-preventive maintenance functions such as "Blow station", "Feeder maintenance notification", and "Nozzle health check" do monitoring and management of Z:LEX's own status.

A PCB range of applications are available fostered by multi-component production market including automotive production lines.

- An extensive range of component supply devices are available including non-stop feeder carts and auto-tray feeders capable of supplying components without having to stop the machine, other choices include stack stick feeders, waffle tray feeders, and bowel feeders for bulk components.

- Linking operation with AOI stops continuous defects from occurring.

Viedo

Feature

Achieves both a whole new dimension of versatility and high-speed for mounters via the 1-head solution

1-head solution

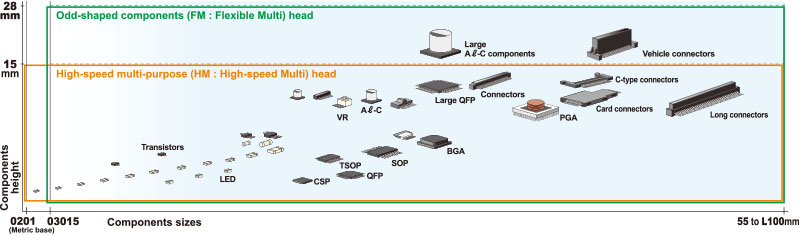

Two types of heads are available that bring the "1-head solution" to an even higher dimension capable of accommodating a wide range of components while maintaining high speed with no head replacement. High-speed general-purpose heads can be used for ultra-small (0201mm) chip components.

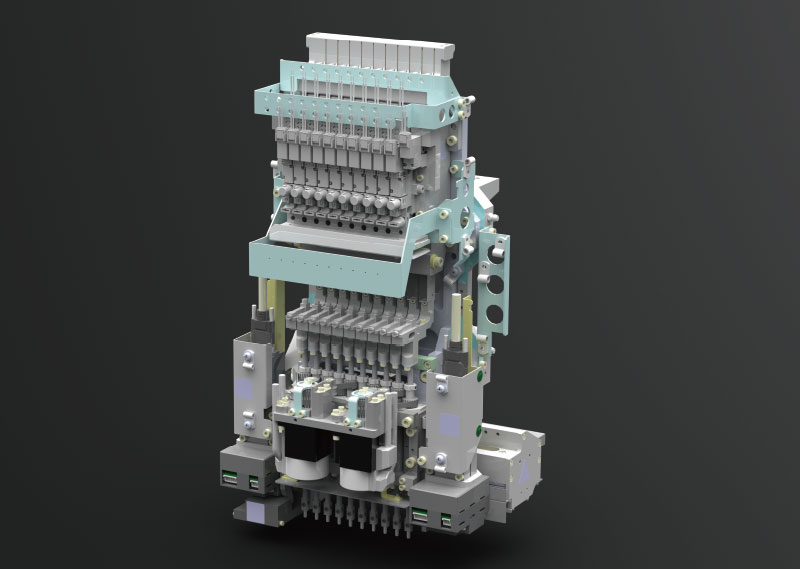

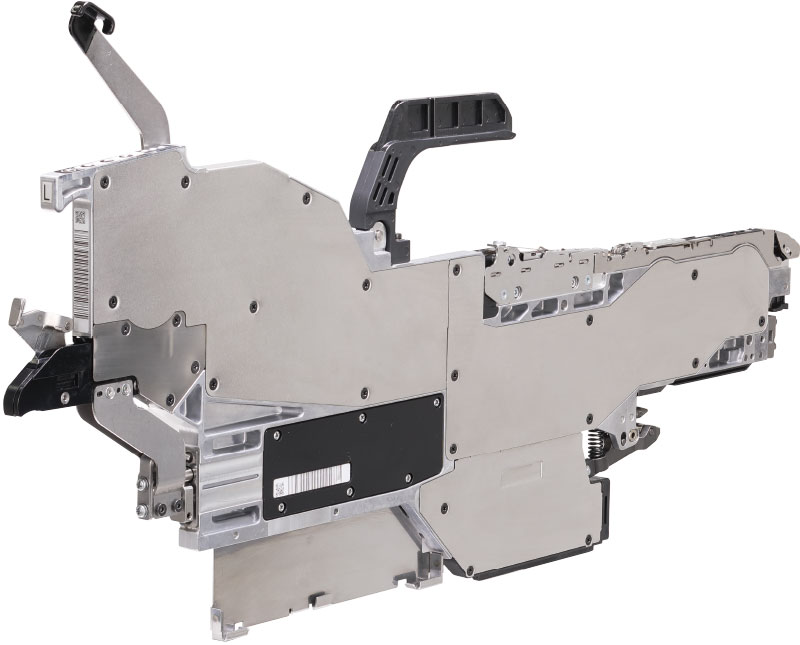

High-speed multi-purpose (HM : High-speed Multi) head

This universal type head made for high-speed mounting and versatility supports from ultra-tiny chips of 0201mm to large-size components of 55 x 100 mm and height of 15 mm.

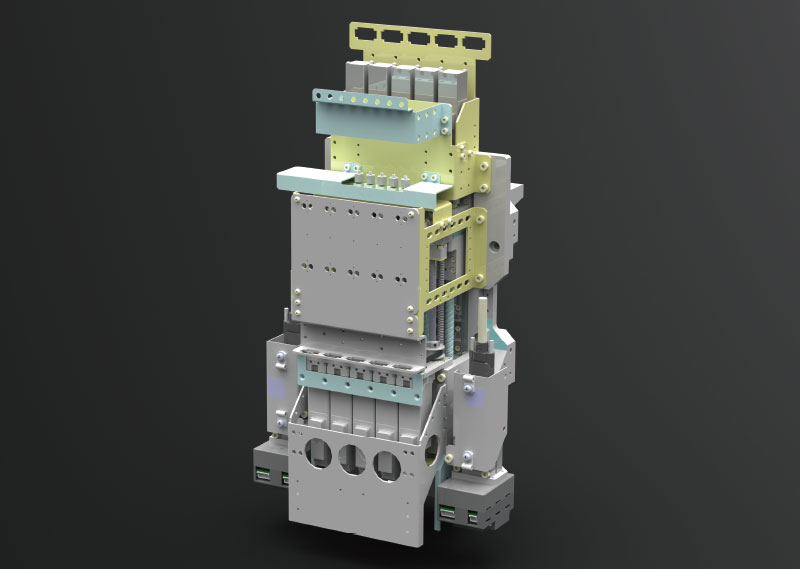

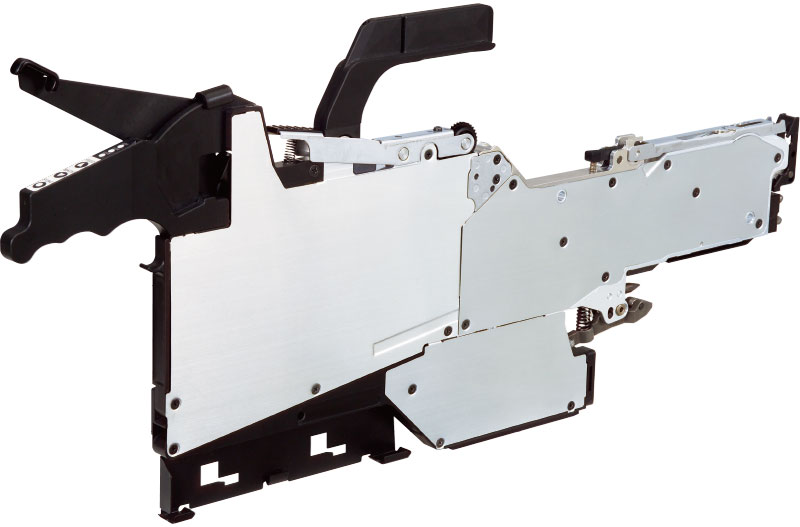

Odd-shaped components (FM : Flexible Multi) head

Super wide-ranging type head supports load control, and handles a broad spectrum of components from ultra-tiny chips of 03015mm, to ultra-large components of 55 x 100 mm and tall components of heights to 28 mm.

Superb mounting performance 95,000 CPH (under optimum conditions as defined by Yamaha Motor)

Improving mounter operation from component pickup to mounting and using high-speed XY axes achieved production of 95,000 CPH which is 5% higher than conventional models.

Huge improved adaptability to actual production

Mounting a new type wide-scan camera increases and expands recognition capability to support high speed mounting of components down to only □8 mm to □12 mm in size. Also, use of side lighting gives high-speed recognition of ball electrode components such as CSP (chip scale packages) and BGA (ball grid arrays).

Beam variations available in 2 types

Achieving a common platform allows selecting from 1-beam and 2-beam for configuring the X-axis according to production mode and mounting capability.

Wide support capability turns the concept of “Limitless EXpansion” into a reality!

Compatible components

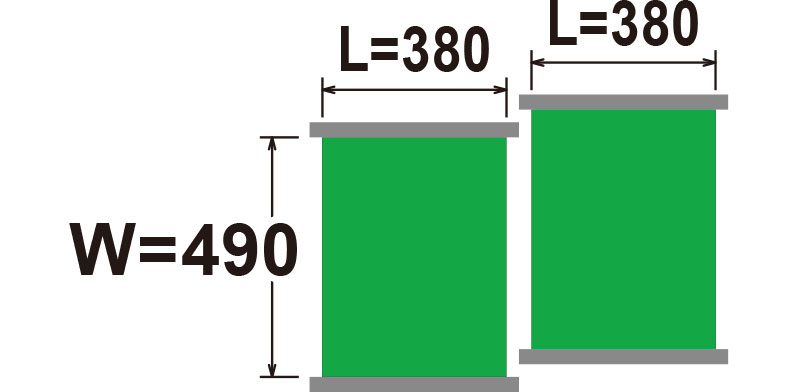

Conveyors available in freely configurable variations

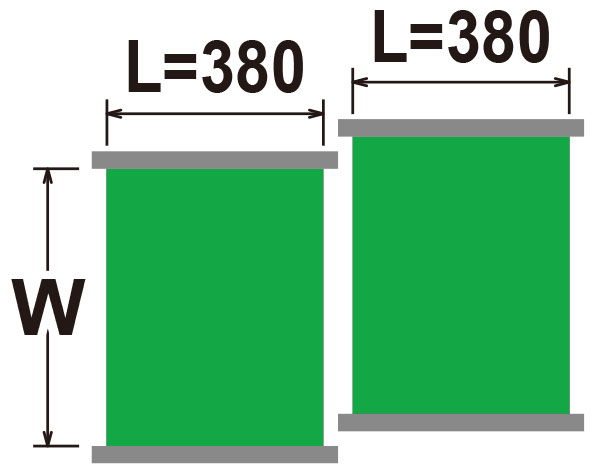

Conveyor system is selectable from dual stage, single lane. Supports PCB sizes to a max.L810 x W490 mm (Dual stage, single lane for conveying single PCB). Single lane also available in M size specifications (max. PCB size L360 x W490 mm) having superior cost performance.

Single lane

W=490

Supports dual-stage single PCB transport

Dual stage (2 PCB conveyance)

W=490

Numerous functions to support high-quality mounting are included as standard features.

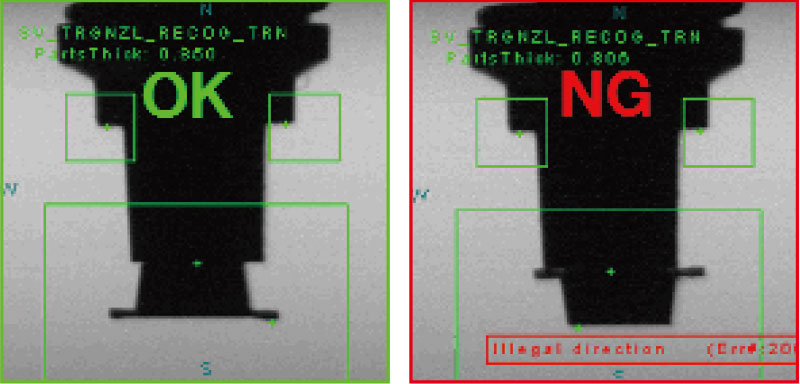

Side view function

Detects pickup status and component’s presenge with no downtime loss.

Blow station

Automatic blow cleaning function keeps nozzle clean for long periods.

High-speed smart recognition

Highly robust “High-speed Smart Recognition” that also creates recognition data for custom or unique components in a short time is now standard equipment.

Achieves highly-streamlined components supply

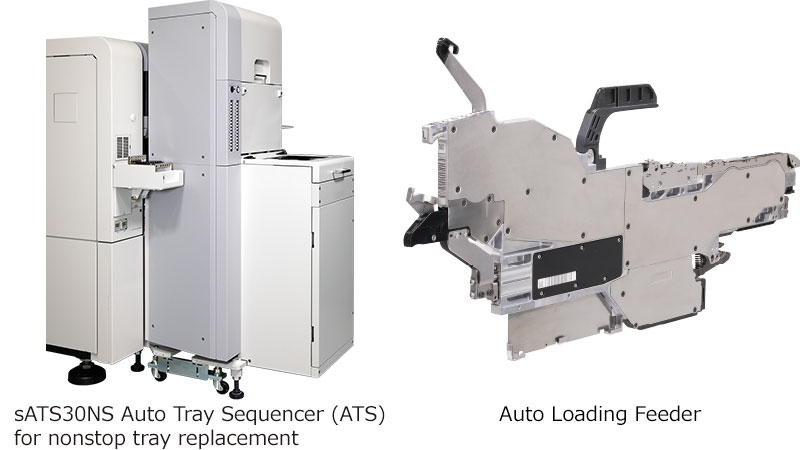

sATS30NS Auto Tray Sequencer (ATS) for nonstop tray replacement

A new function has been added to the sATS30 Auto Tray Sequencer for automatic tray exchange and component feed. This new function automatically ejects pallets with empty trays during operation and feeds pallets with new trays into the machine. Operator can remove the pallet with empty tray and replenish pallet with full tray and press feed button. Pallet will automatic be supplied into the magazine. The magazine can be exchanged during changeover without stopping automatic operation.

sATS30NS

Nonstop feeder carriage exchange system

A cover with shutter was mounted on the pickup components of the opening used during carriage clamp and release. The shutter automatically closes when the carriage is detached so that carriages can be exchanged without stopping the machine. This improve the machine productivity.

Newly developed and designed Auto Loading Feeder

Newly developed Auto Loading Feeder can supply tape-mounted components just by inserting a tape without stopping the machine. The unique center open technique from Yamaha drastically reduces components pickup errors that occur from static electricity and the residue when peeled from the tape. No recovery of top tape is needed which vastly increases the operating rate.

ZS feeder

Also supports thin, light-weight, compact, single lane type motorized intelligent feeders. Customer can select from non-stop feeder replacement function specs. Specs also support conventional SS feeders.

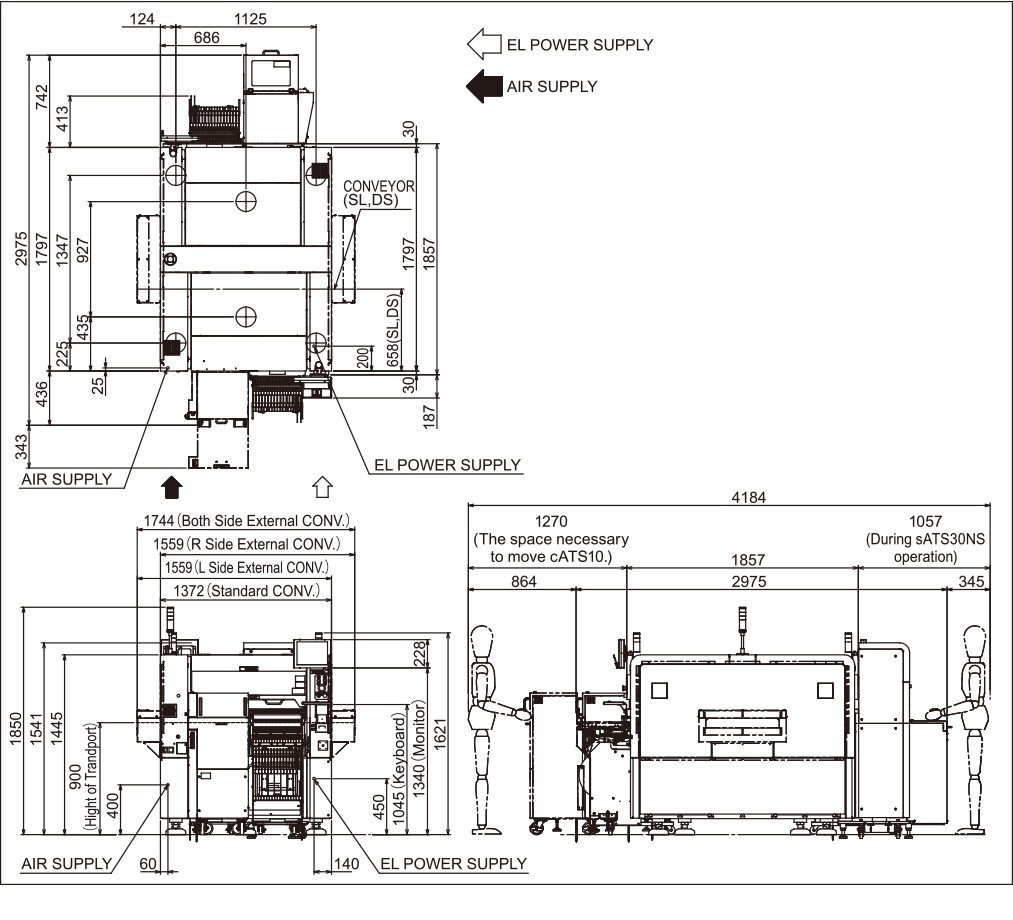

Specifications, External dimension

Specifications

| Model | Z:LEX YSM20R |

|---|---|

| Applicable PCB | Single lane:L810 x W490 to L50 x W50

Dual stage Note: For X-axis 2-beam option only 1PCB conveyance: L810 x W490 to L50 x W50 2PCB conveyance: L380 x W490 to L50 x W50 |

| Head / Applicable components | High-Speed Multi (HM) Head *

0201mm to W55 x L100mm, Height 15mm or less Odd-shaped components (FM: Flexible Multi) head: 03015mm to W55 x L100mm, Height 28mm or less |

| Mounting capability (under optimum conditions as defined by Yamaha Motor) |

X axis 2-beam: High-speed multi-purpose (HM: High-speed Multi) head x 2 95,000CPH |

| Mounting accuracy | ±0.035mm (±0.025mm) Cpk≧1.0 (3σ) (under optimum conditions as defined by Yamaha Motor when standard evaluation materials are used) |

| Number of component Types | Fixed plate: Max. 140 types (conversion for 8mm tape feeder)

Feeder carriage exchange: Max. 128 types (conversion for 8mm tape feeder) Trays for 30 types (Fixed type: max., when fitted with sATS30) and 10 types (Carriage type: max., when fitted with cATS10) |

| Power supply | 3-Phase AC 200/208/220/240/380/400/416V +/-10% 50/60Hz |

| Air supply source | 0.45MPa or more, in clean, dry state |

| External dimension (excluding projections) | L 1,374 x W 1,857 x H1,445mm (Main unit only) |

| Weight | Approx. 2,050kg (Main unit only) |

* Please contact us for info regarding mounting 0201mm components.

Specifications and appearance are subject to change without prior notice.

External dimension