EAGLE 3D 8800 TWIN

3D Automated Optical Inspection system Top/Bottom Double Sided simultaneous inspection

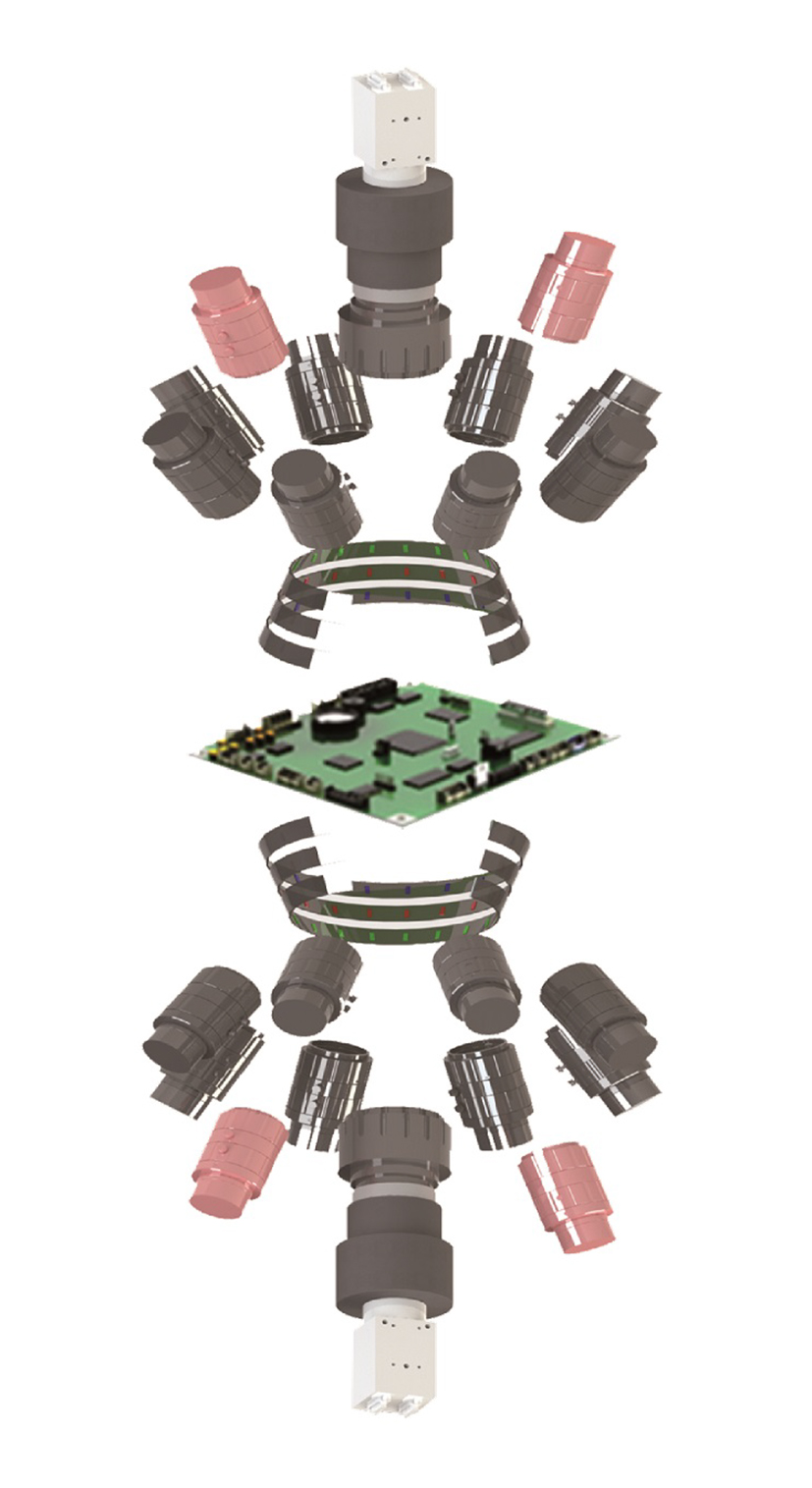

PEMTRON’s new head type has been upgraded from the existing head for 3D formation that is identical to the real image and is more stable based on the accumulated technology for decades.

- Simple Head Composition

- More Space, Convenient Maintenance, Easy Assembly and Setting - Improved Repeatability

- Accurate 3D makes repeatability more reliable. - Advanced High-Speed Inspection and Measurement Technology

- Simultaneous Inspection Algorithm (2D and 3D)

- Telecentric Lens for optimal accuracy - Lean & Efficient full line control capability

- Proven for world’s best 3D-imaging quality

- Absolutely world’s most innovative & flexible solutions

- Unique 3D technology not found anywhere else

- 4-Way side cameras (Optional)

- Possible to detect inside the connector - Convenient Teaching by using the existing Algorithm

Video

Technology and Features

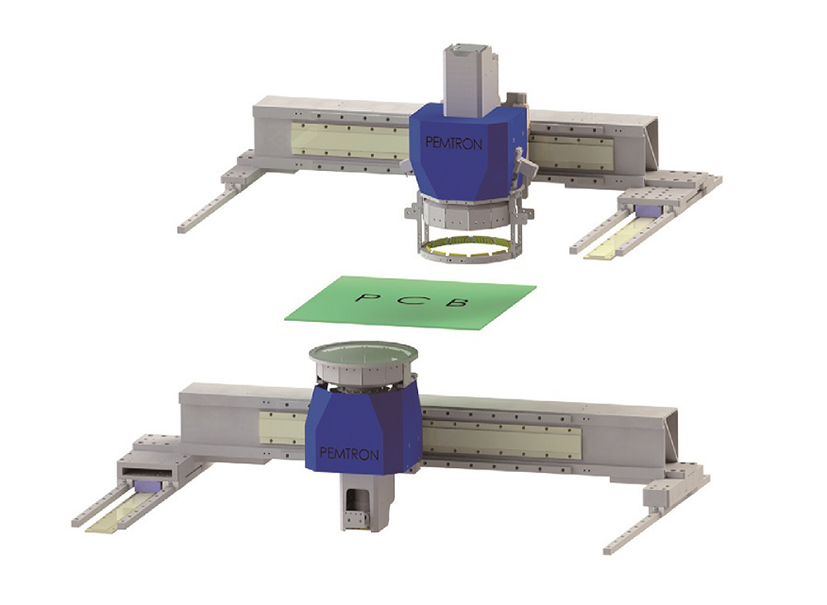

Simultaneous Top / Bottom double sided Inspection

No time loss

Full performance Full speed

Multi-configurable

Advanced High-Speed Inspection and Measurement Technology

Lean & Efficient full line control capability

Proven world best 3D imaging quality

Absolute world most innovative & flexible solutions

Unique 3D technology not possible anywhere else

4-Way Side Camera (Option)

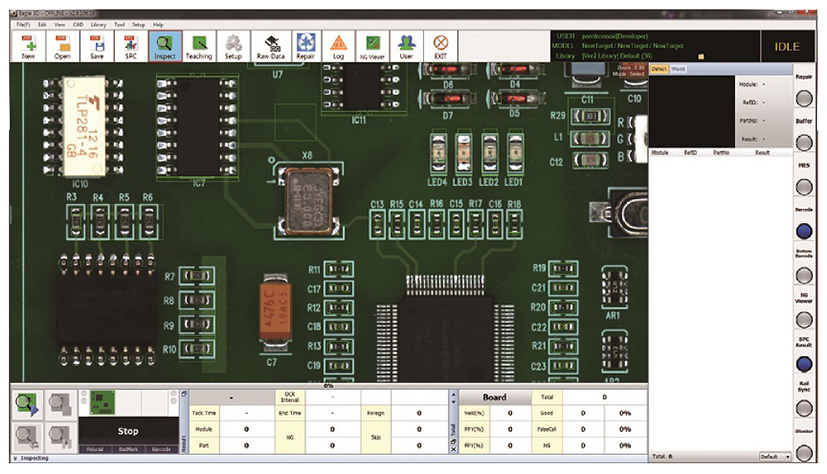

Simple & Intuitive User Interface

Same UI configuration of AOI allows existing users to use easily

Simultaneously display of all results of both sides

Both the TOP / BOTTOM can set AOI and TH inspection

Simple & Intuitive User Interface

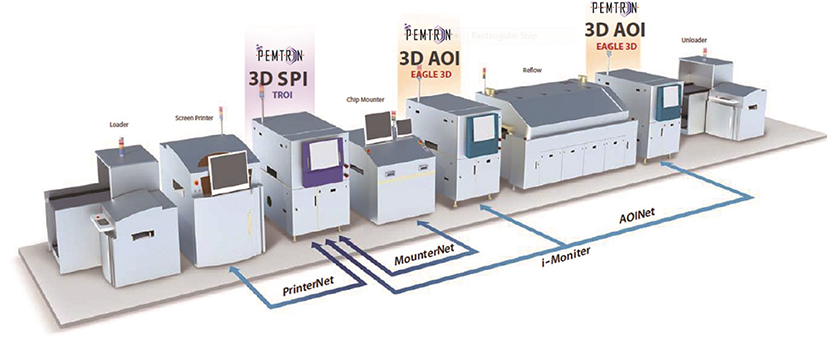

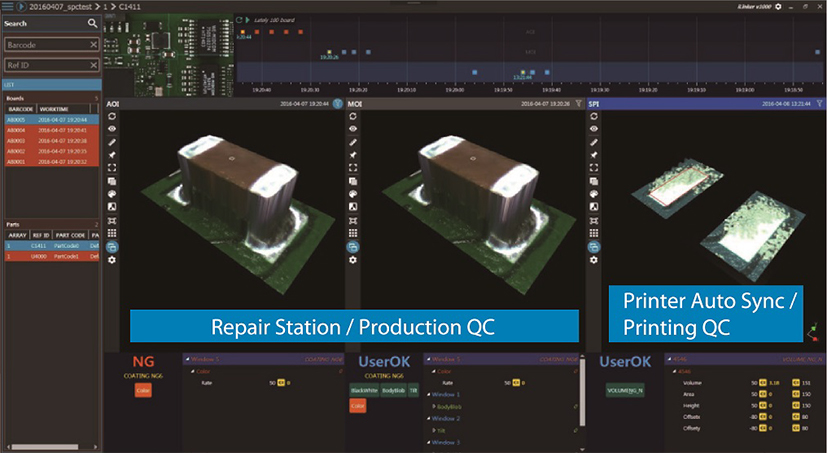

REAL-TIME PROCESS MANAGEMENT QUALITY MANAGEMENT SOLUTIONS

Inspection Result Information auto Sync

Printer Net

- Closed Loop Solution with Screen Printer

PEMTRON SPI & AOI Closed Loop Function

- Real-time defect confirmation

Mounter Net

- Closed Loop Solution with Mounter

- Bad Mark Mounter Sync and Adaptive Process Control

Monitor

- Control a maximum of twelve on one monitor

APC MFB

- Offset Technology of Mounting Location of Mounter, Using Data of AOI Inspection

SPI & AOI Linkage

Statistical Process Control

Pemtron's SPC module collects and analyses the inspection data,calculates and displays the data at a glance A robust SQL driven database lends the user the flexibility of sorting and exporting the desired production results in a multitude of ways.

The optional SPC Server collects data from multiple inspection systems over SMT lines. all in one system and interface.

Specification

| Machine Model | EAGLE 3D - 8800 TWIN | EAGLE 3D - 8800 TWIN PRO | ||

|---|---|---|---|---|

| Camera | 10MP | 12MP | ||

| X/Y Pixel Resolution | 10um | 15um | 18um | 15um |

| Inspection Speed | 19.2cm2/s | 43.2cm2/s | 61.5cm2/s | 54 cm2/s |

| FOV | 32 x 30 mm | 48 x 45 mm | 57 x 54 mm | 45 x 60 mm |

| Height Range | 0 - 5.5 mm(Option: 27 mm) | |||

| Height Accuracy | ±3% | |||

| Max. PCB Warpage | ±3mm | |||

| PCB Size | 50 * 50 - 510 * 510 mm | |||

| PCB Thickness | 0.4 - 7.0 mm | |||

| PCB Clearance | Top: 50 mm Bottom: 50 mm | |||

| Power Requirement | 220-240Vac , Single Phase, 50/60 Hz | |||

| Dimensions | 1660 x 2500 x 1990mm | |||

| Weight | Approx. 1650Kg | |||