Jupiter XT3-M130 (3D AXI)

Key Features

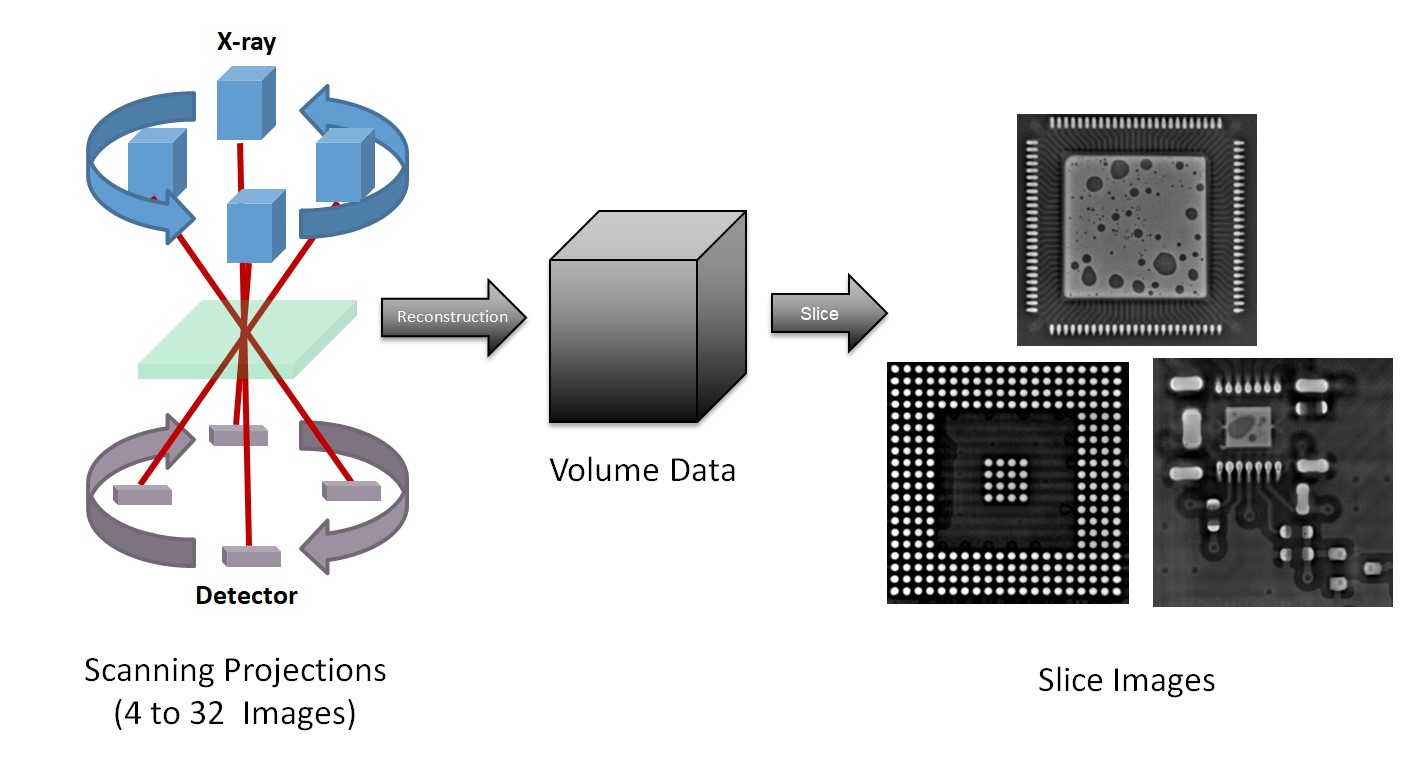

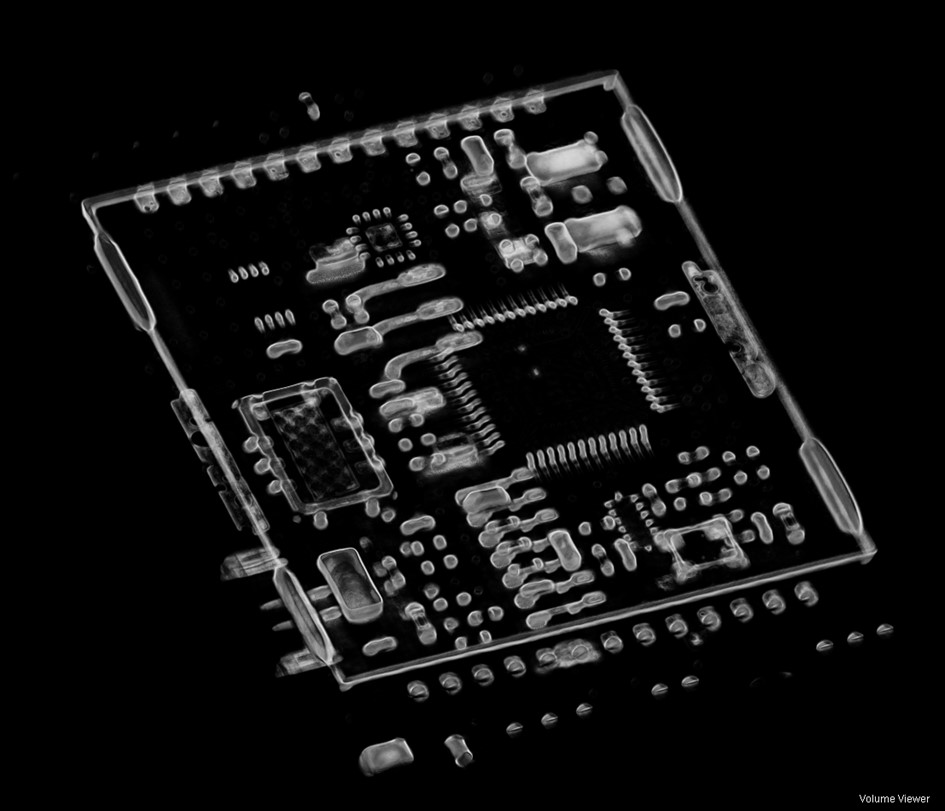

- 3D X-ray inspection using PCT reconstruction based processing

- Covering full in-line inspection by flexible 3D or 2D configuration

- Integrated optical camera for 2D vision inspection.

- Various defect detection algorithms proven from AOI system

- High-speed and accurate motion system used for AOI Machines.

- Process quality analysis by data sharing with AOI and SPI

Planar CT

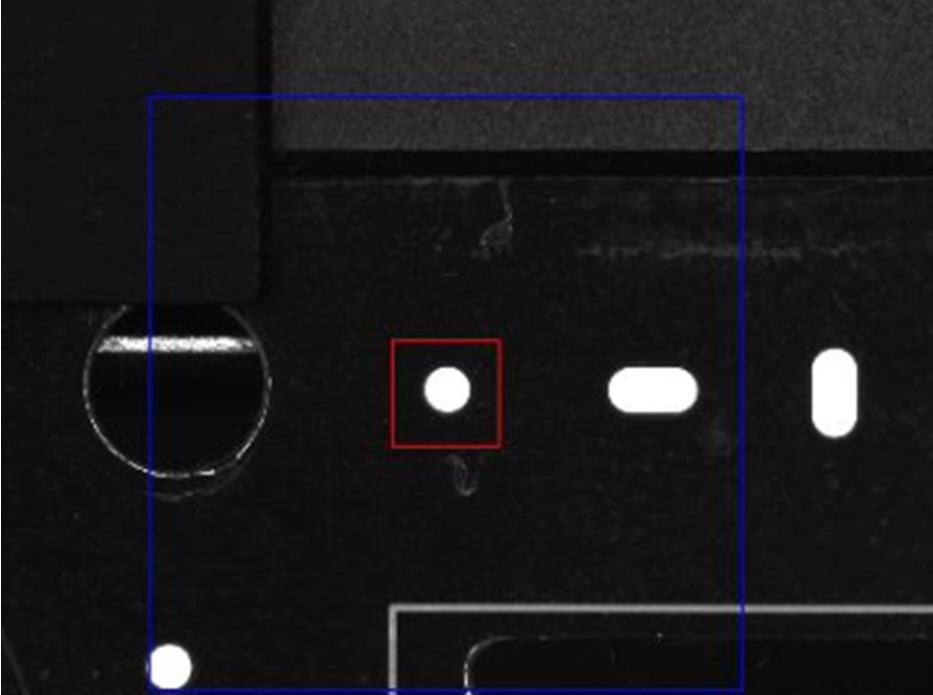

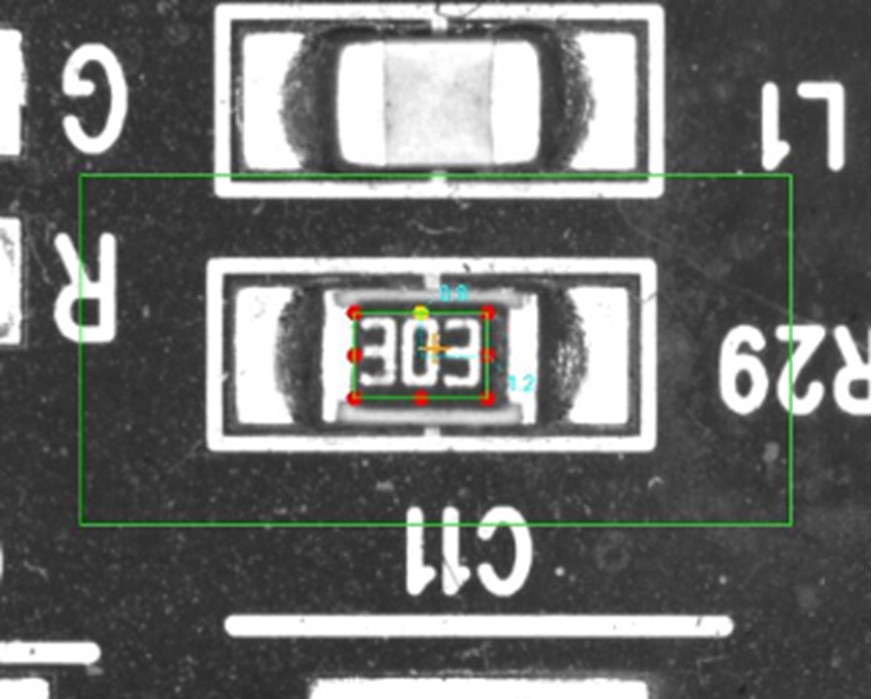

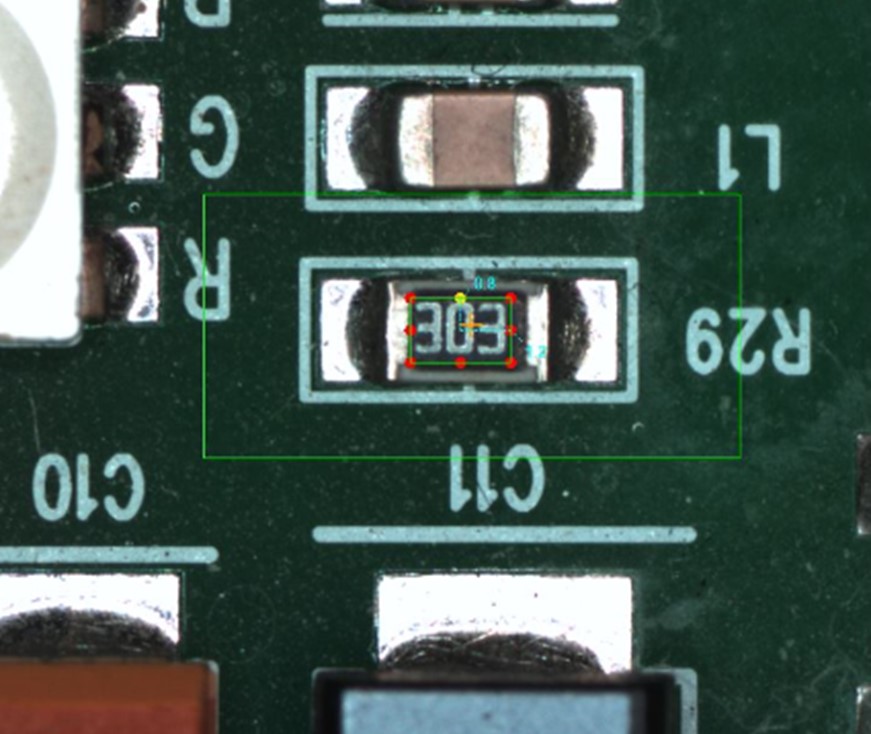

Optical camera

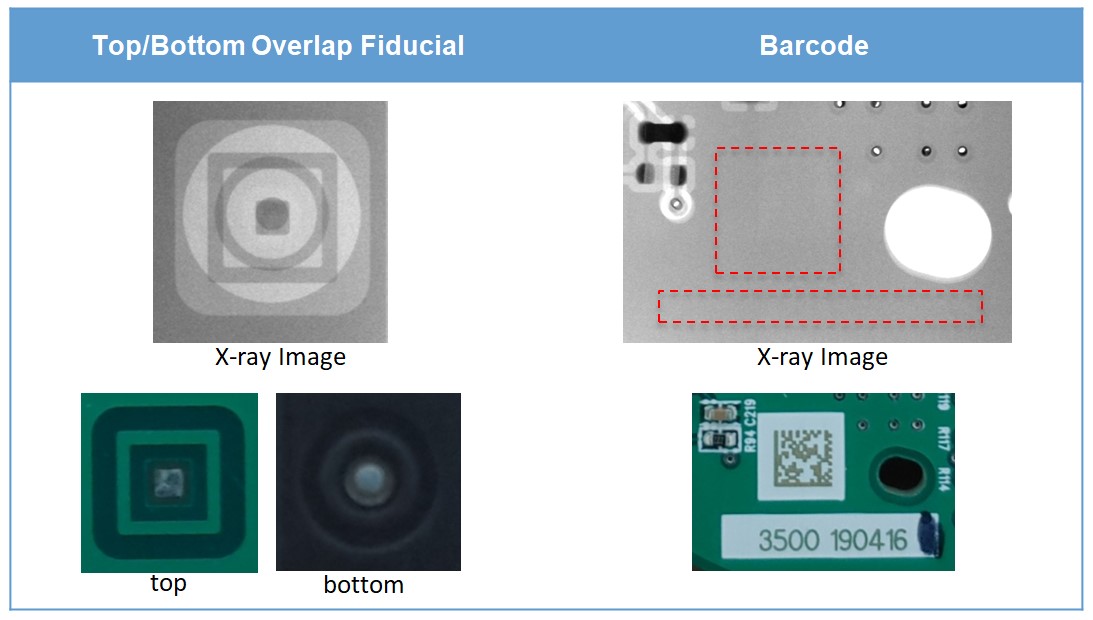

2D Vision inspection by integrated optical camera

- Recognizes Fiducial, Barcode and Bad mark.

- Inspects OCR, Foreign objects

Case study :

- Some Fiducials are hard to recognize on X-ray image

- Printed Barcode or Badmark can not be seen in X-ray image

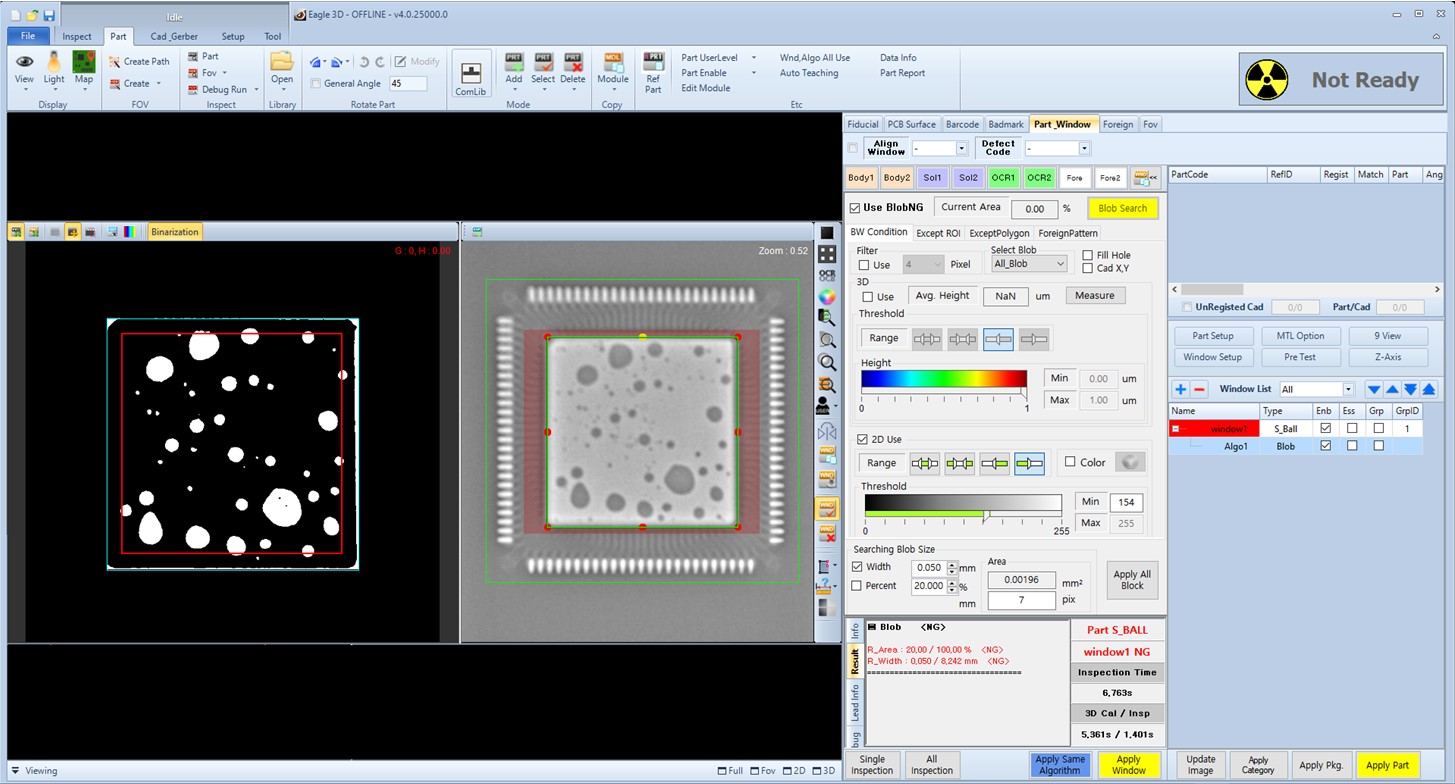

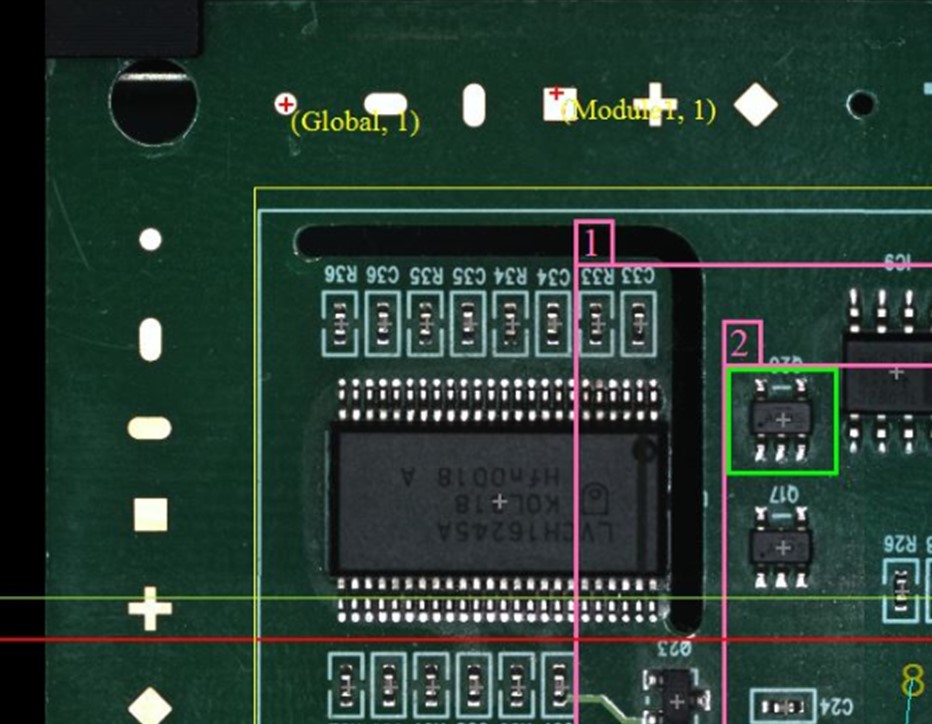

AOI based User Interface

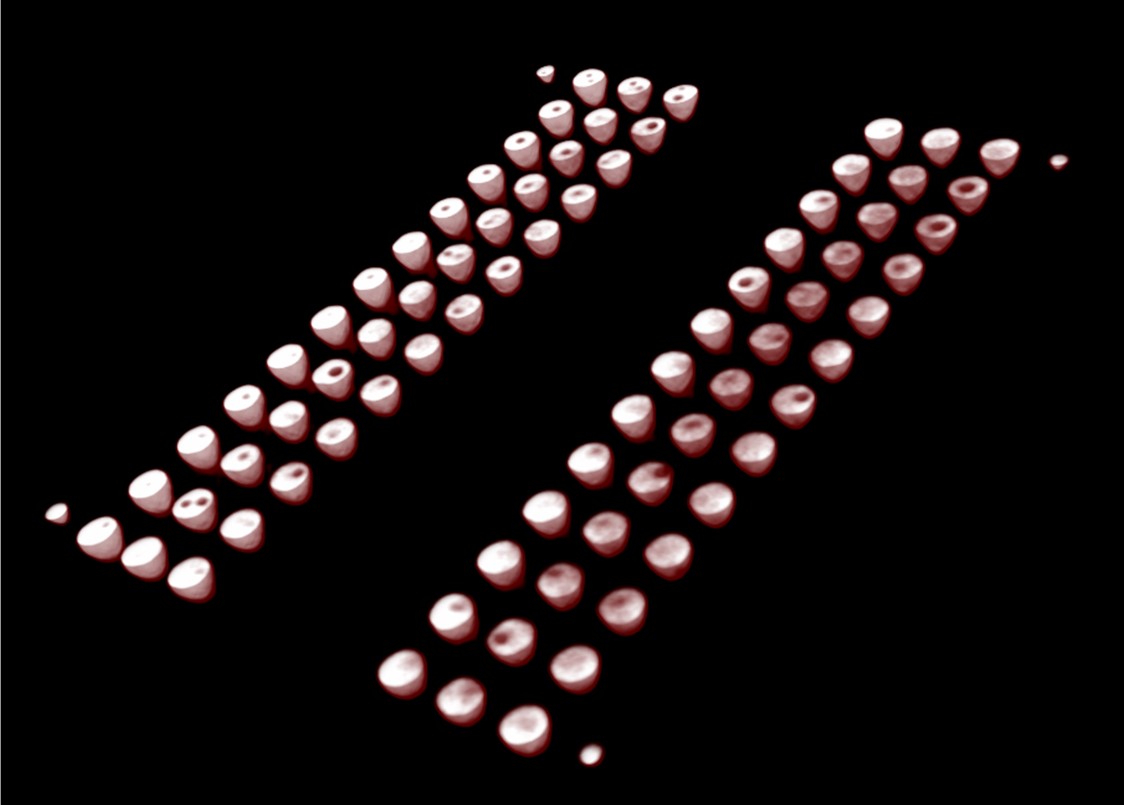

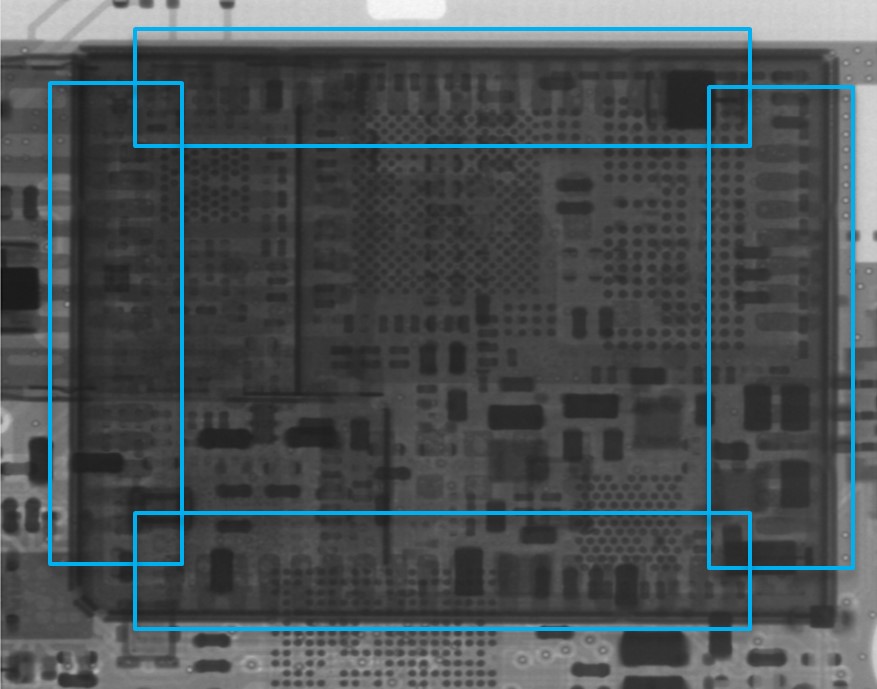

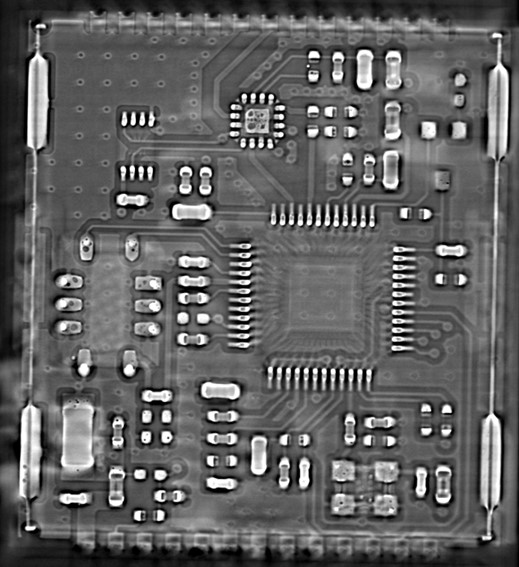

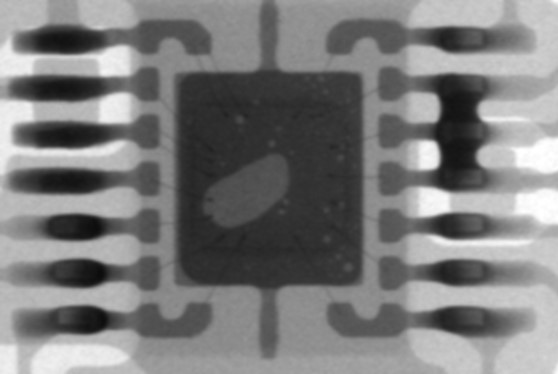

BGA Inspection

Sample

Volume

Slice

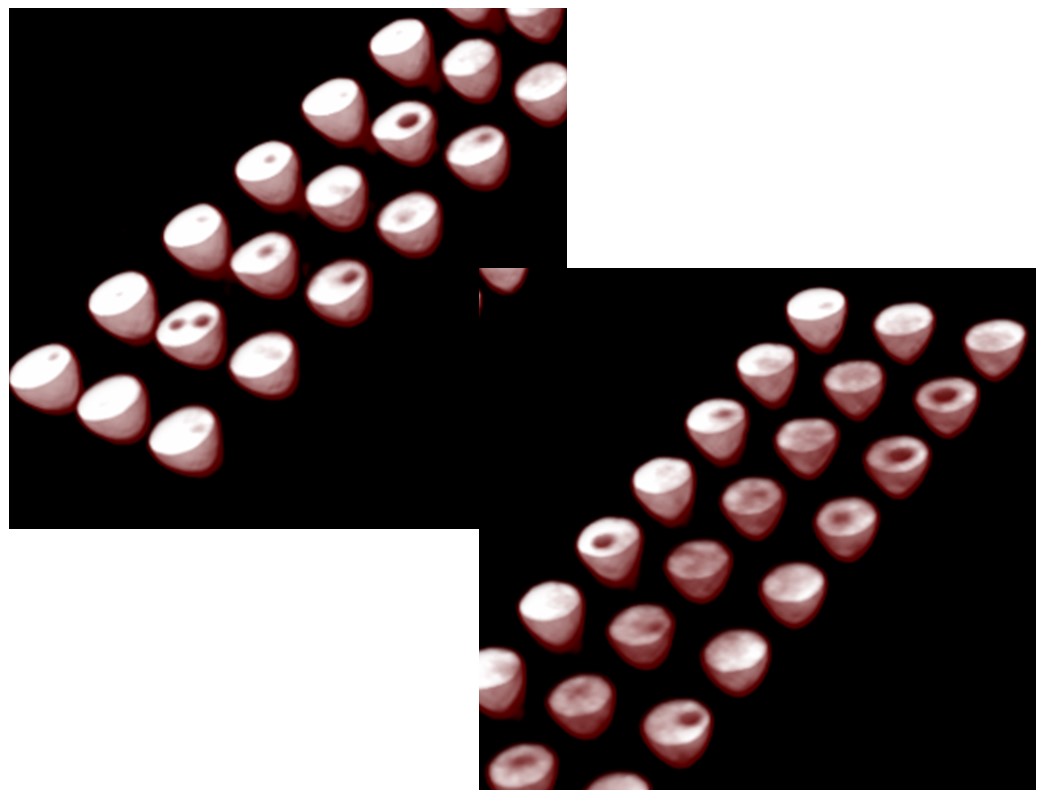

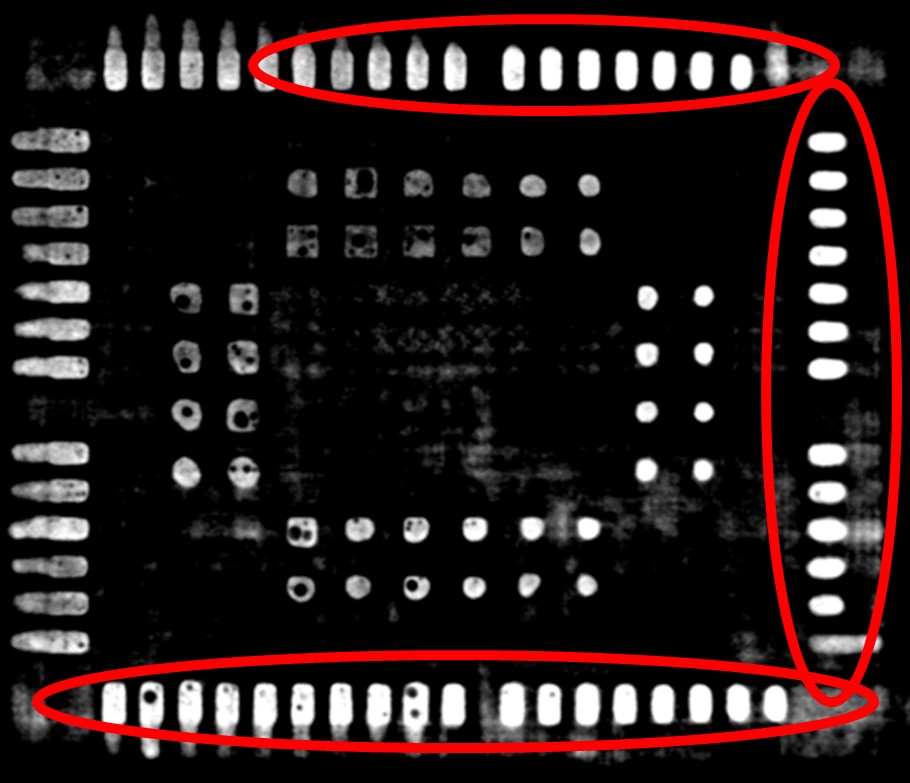

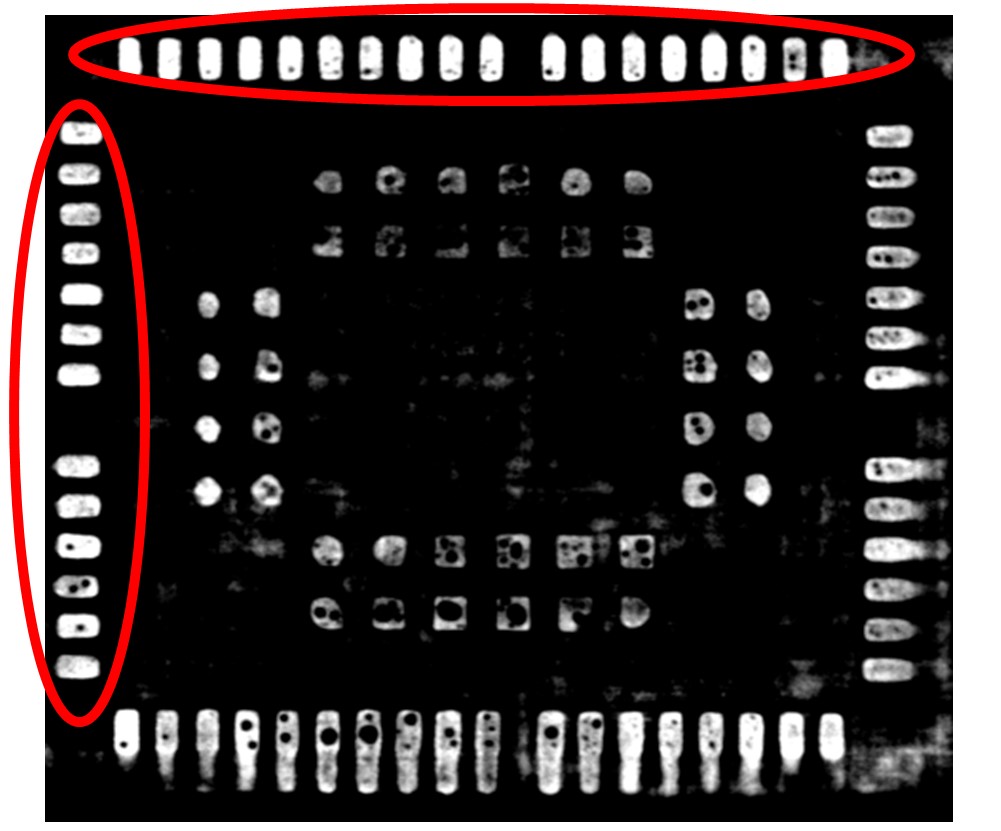

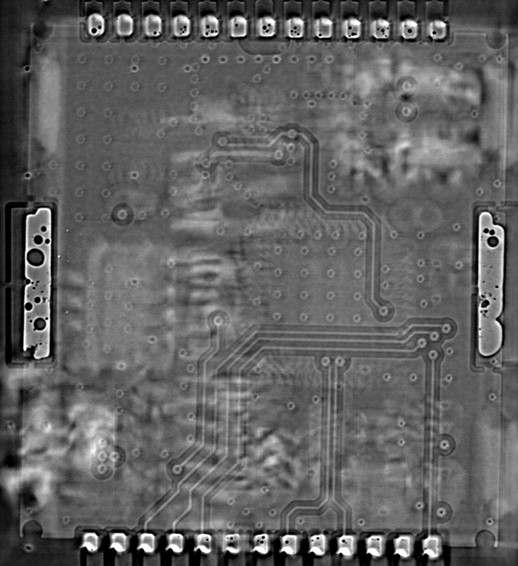

Non-wet Inspection

Sample

2D

Difficult to inspect from 2D image!

Slice

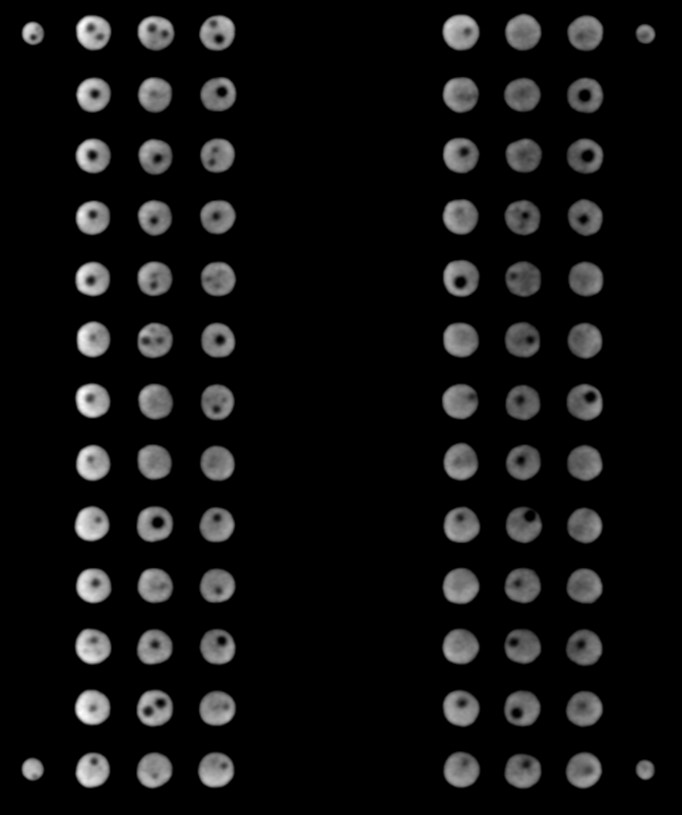

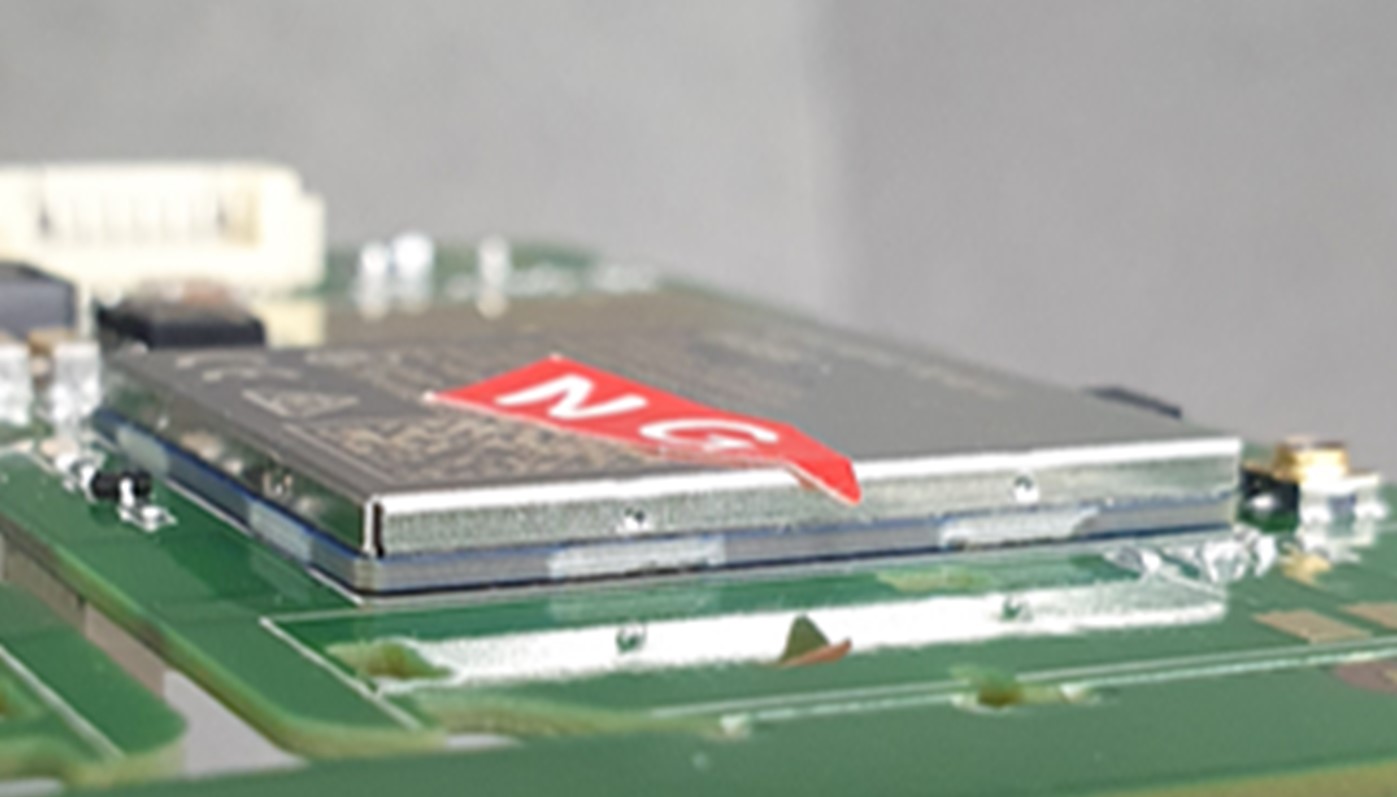

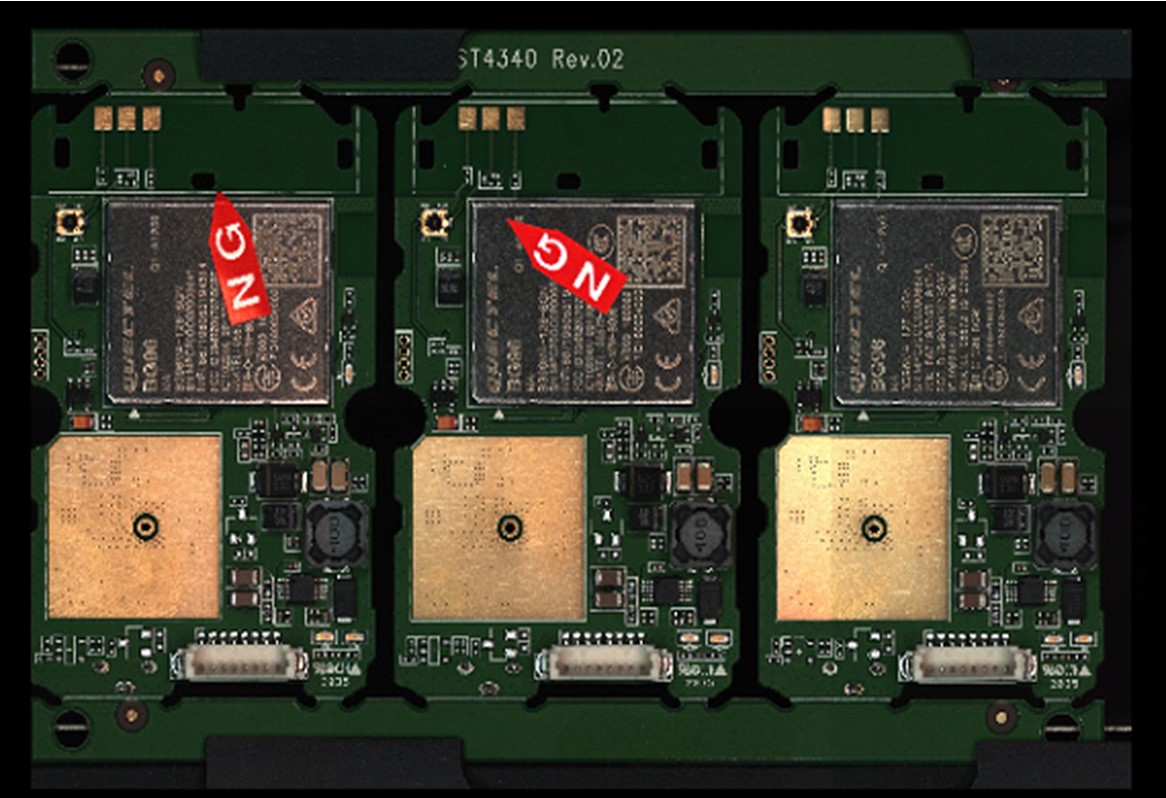

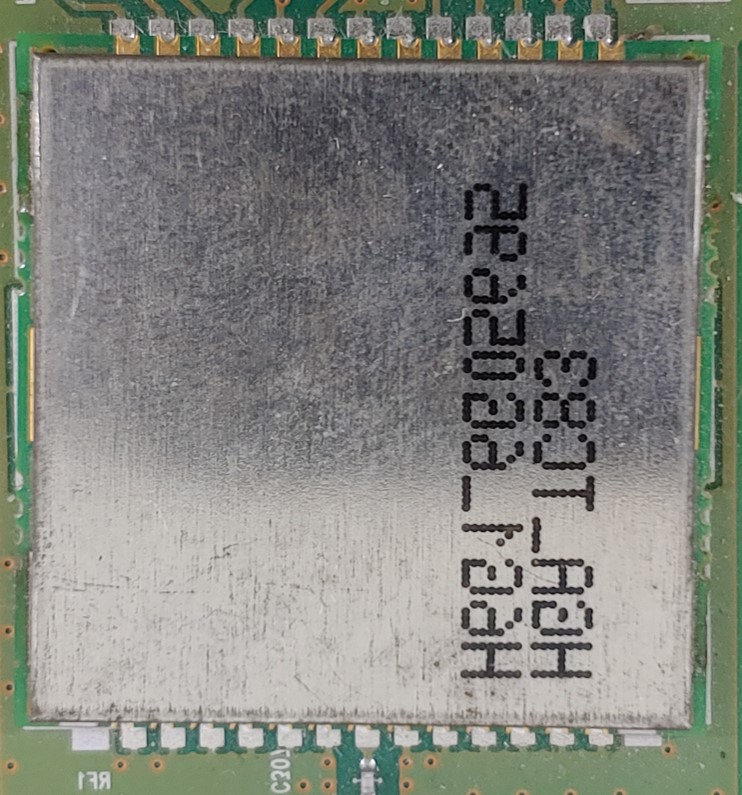

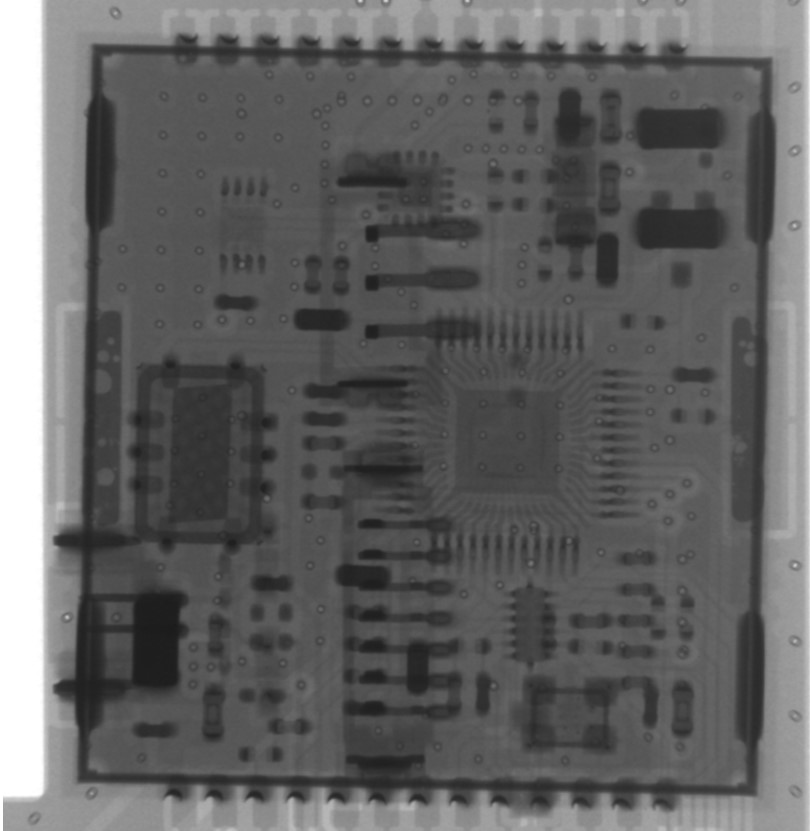

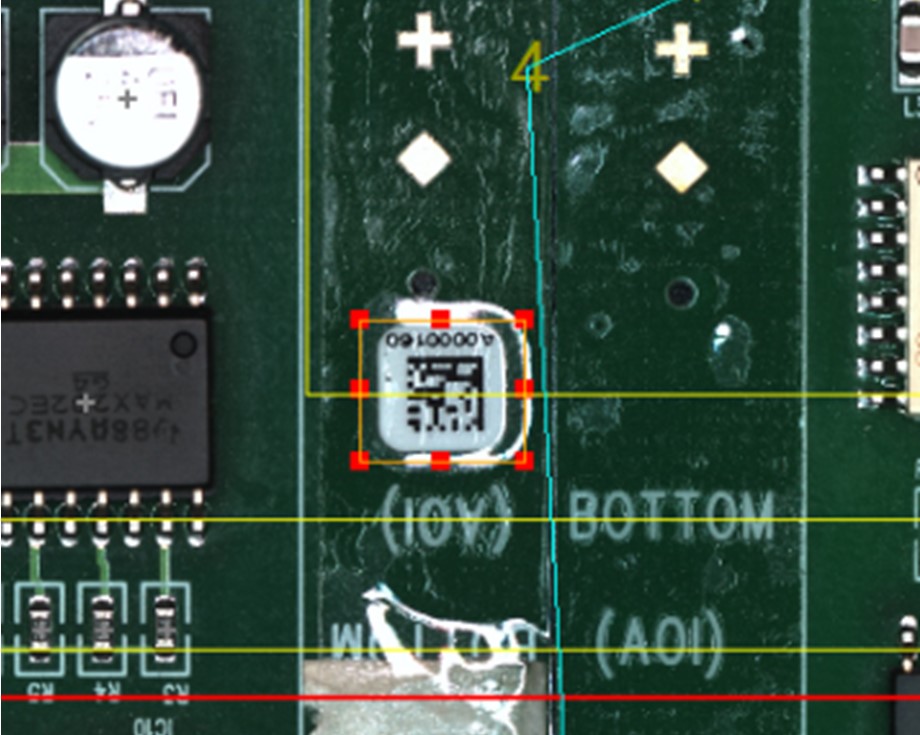

Shield Can Inspection

Shield Can

(Top / Bottom)

2D

Volume

Slice

(Top, Middle, Bottom)

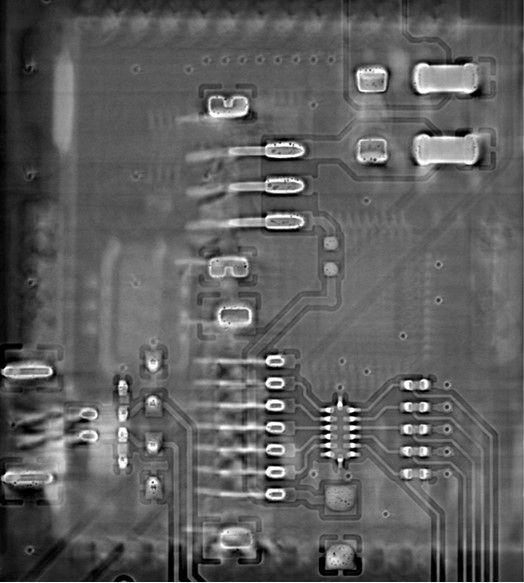

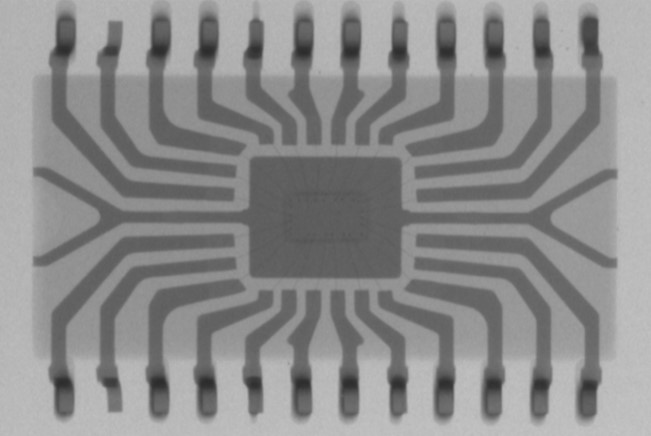

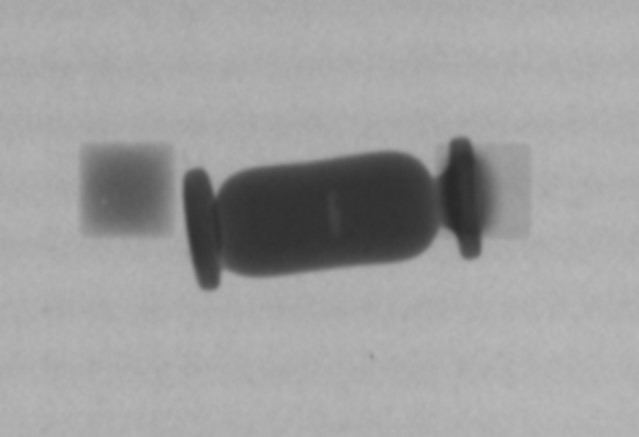

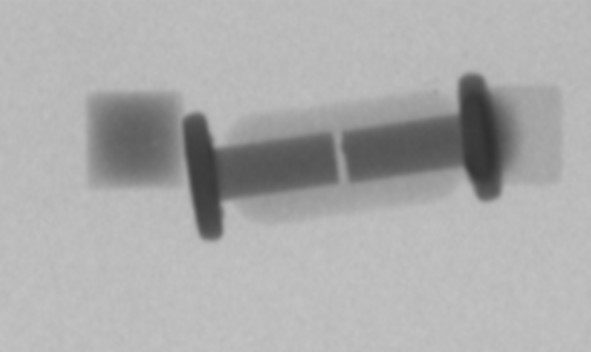

2D X-ray Inspection

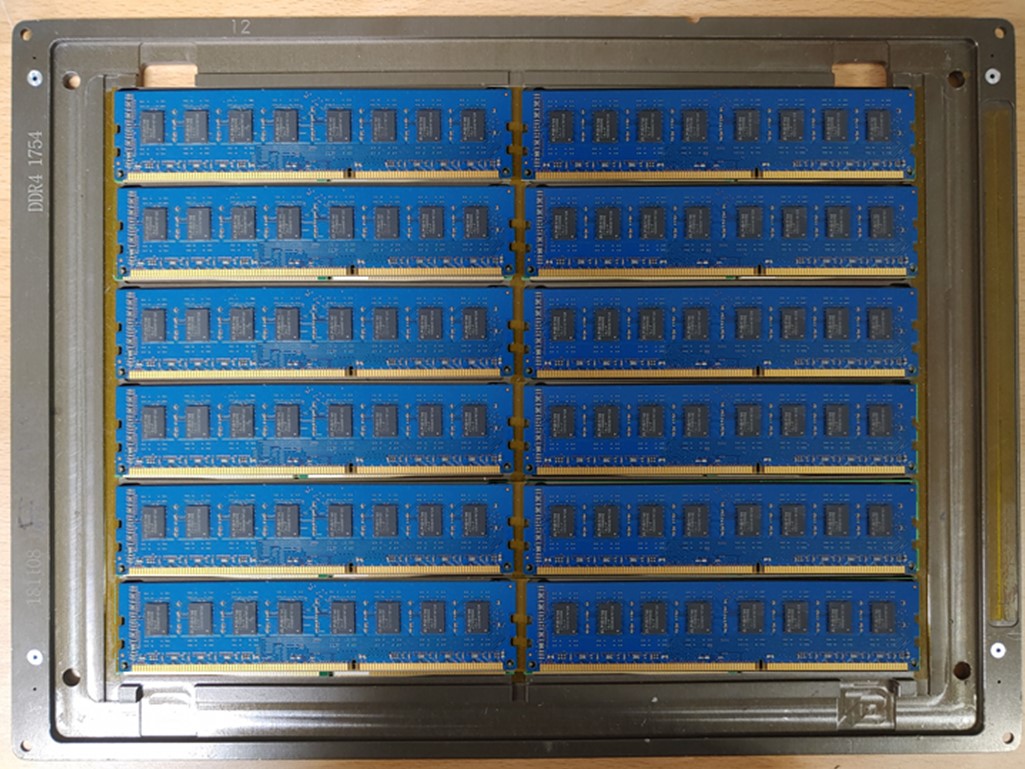

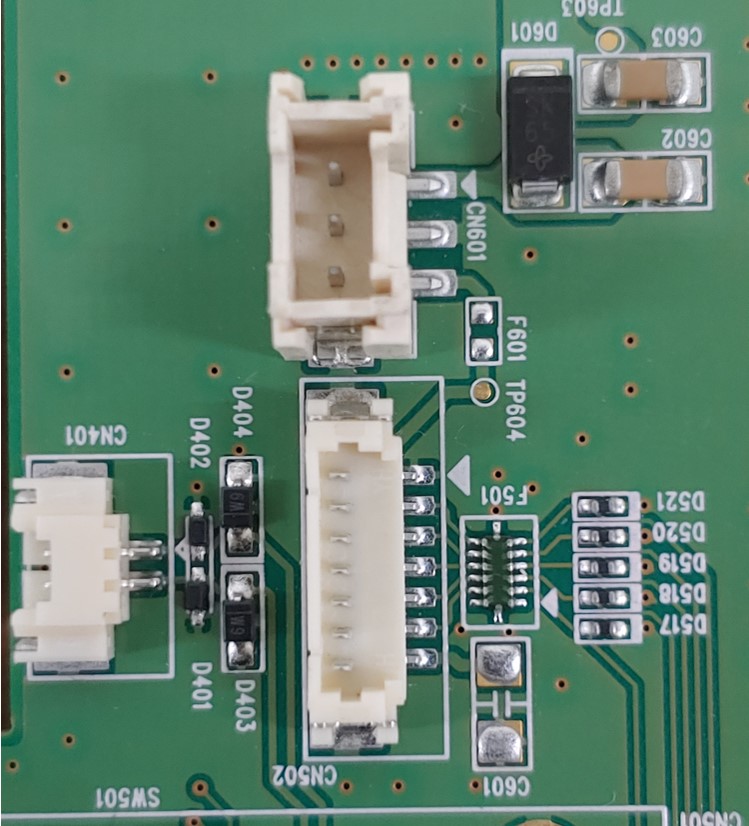

AOI Test Board

SOIC

Diode

Chips

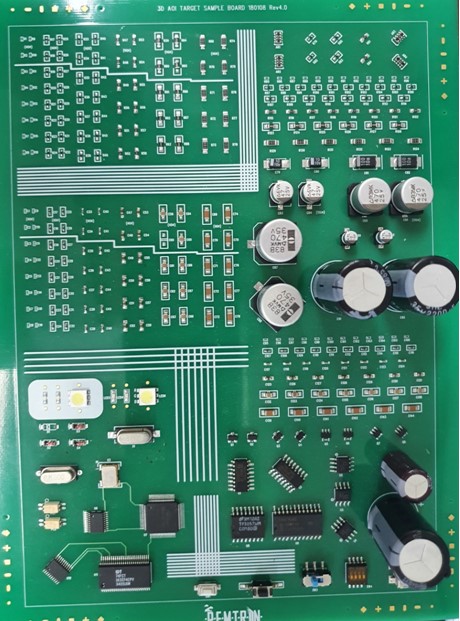

2D Vision Inspection

Fiducial

Barcode

OCR

Layout

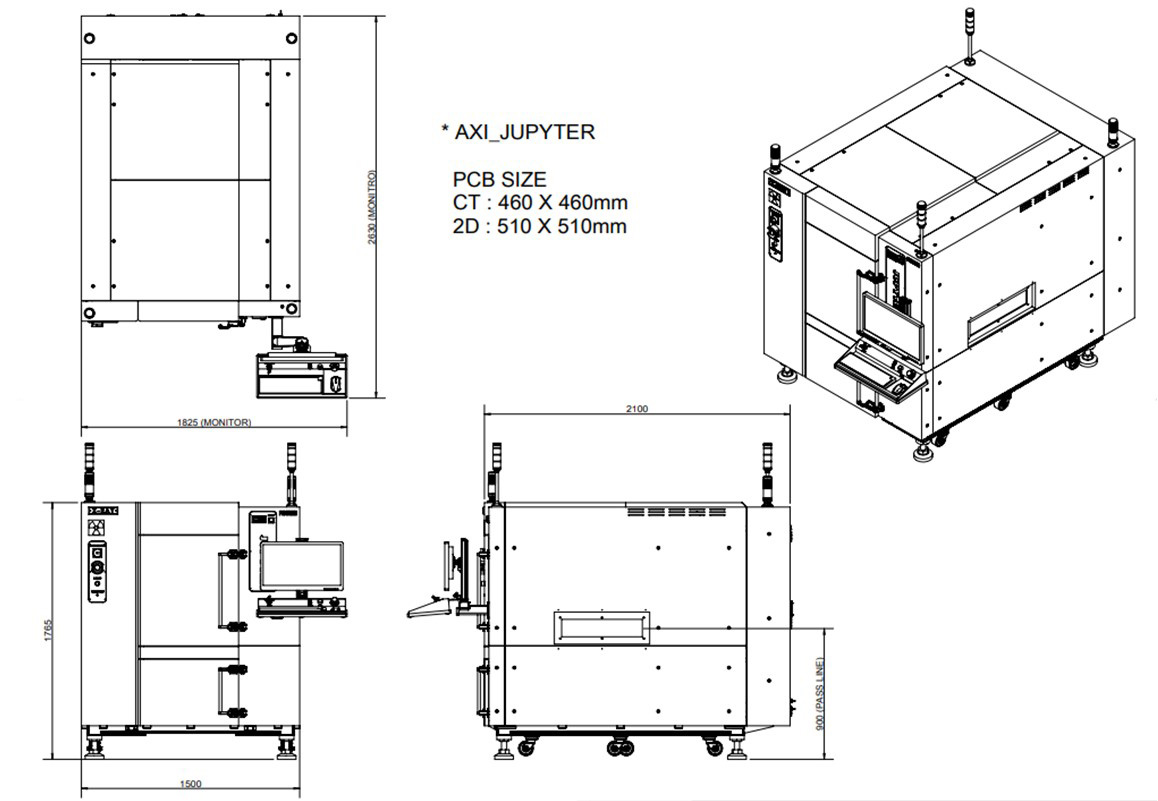

Specification

| Inspection | |

|---|---|

| Objects | BGA/CSP, QFN, R/C Chips, SOP, QFP, etc |

| Items | Mount: shift, missing, tombstone |

| Soldering : solder amount, void, bridge, non-wet | |

| Etc : foreign material | |

| Image | |

|---|---|

| Resolution | 5 ~ 20㎛ |

| CT projection # | 4, 8, 16, 32 selectable |

| Inspection Area | 2D : 510x510㎜, CT : 460x460㎜ |

| Speed | |

|---|---|

| 2D | 0.3 sec / fov |

| 3D (PCT) | 3.0 sec / fov @8-projections |

| PCB | |

|---|---|

| Size | 100x50 ~ 510x510㎜ |

| Thickness | 0.4 ~ 7㎜ |

| Clearance | Top : 15㎜@5㎛, 45㎜@10㎛, 100㎜@>15㎛ |

| Bottom : 50㎜ | |

| Side : 4㎜ | |

| Machine | |

|---|---|

| Dimension | 1500(W) x 2100(D) x 1765(H) ㎜ |

| Weight | 3300 ㎏ |

| Utility | Electric : 220V, 1-phase, 50/60㎐ |

| Air : 6 Bar | |

| X-ray | |

|---|---|

| Type | Micro focus closed type |

| Voltage | 130 ㎸ |

| Current | 500 ㎂ |

| Power | 56 W |

| Focal spot | <8um @4W |

| Detector | |

|---|---|

| Type | CMOS Flat panel detector |

| Resolution | 2352x2944 pixels |