High-speed、high-quality printer that achieves completes automatic setups and changeovers. It also supports both single lane and dual lane production.

- High-speed printing performance Core cycle time: 6 seconds

- Printing accuracy μ±6σ : ±16μm Cpk≧2.0(Measured using CeTaQ under optimum conditions of YAMAHA)

- Completely automated setups and changeovers.

- Dual lane fully independent production

Function and Feature

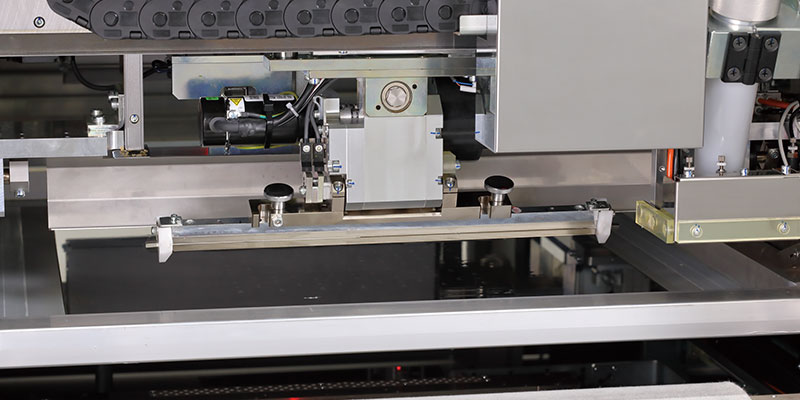

High-quality, highly durable single head that is easy to handle single head

Dramatically reduces man-hours by completely automatic setups and changeovers

Automatic setup function and dual-lane production

W330 mm large PCB dual lane transfer

Promotion Movie

Delivers both high quality & super-accurate printing!

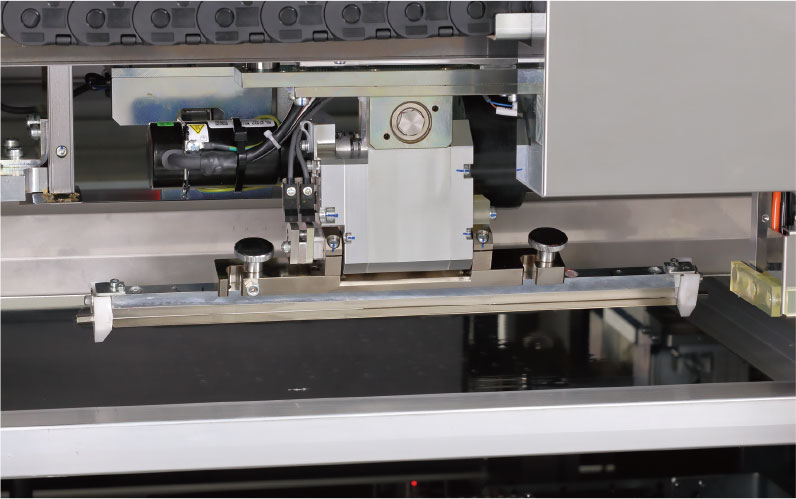

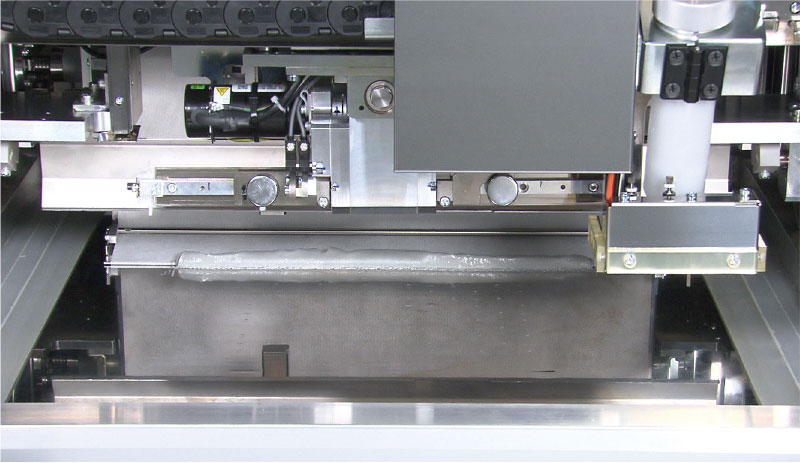

YAMAHA’s original 3S head[3S:Swing Single Squeegee]

Program change squeegee attack angle and speed to an ideal setting to provide optimal printing conditions that match the solder being used.

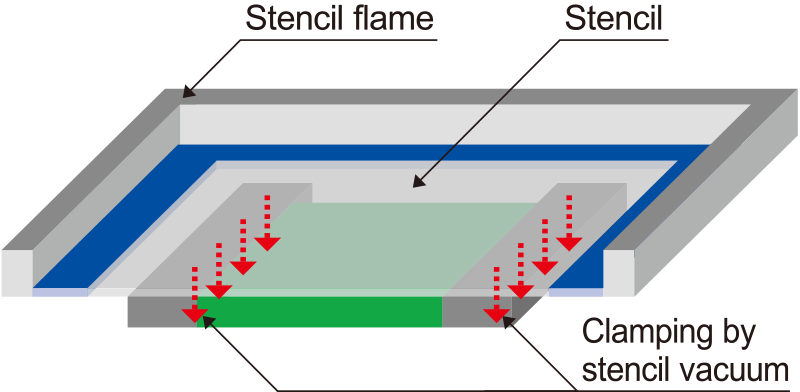

Stencil vacuum

A stencil vacuum mechanism delivers consistent high accuracy printing with no effects from stencil droop. Also drastically cuts the setup time since no offset entry is needed during back and forth printing movement.

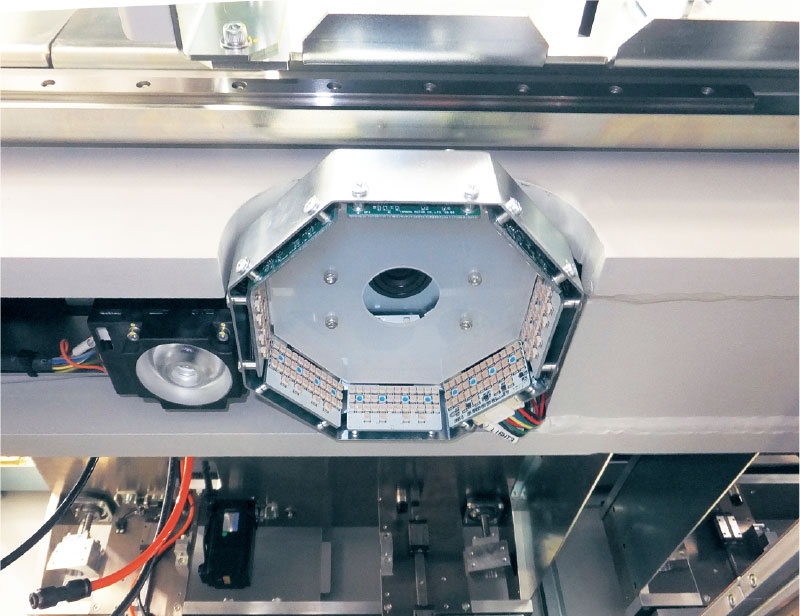

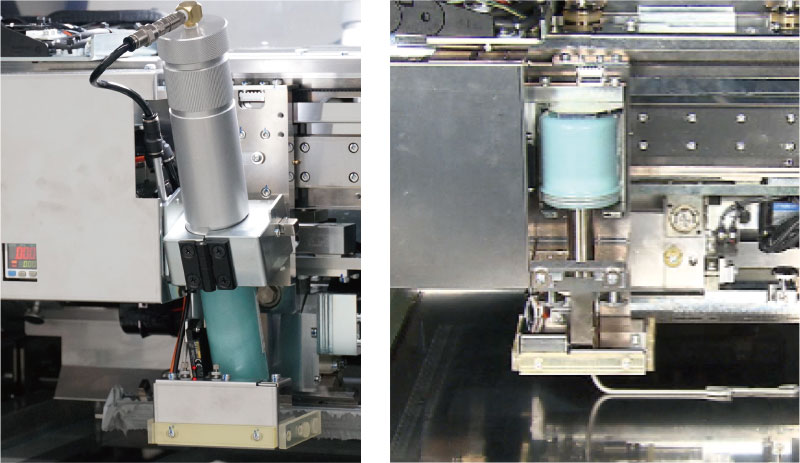

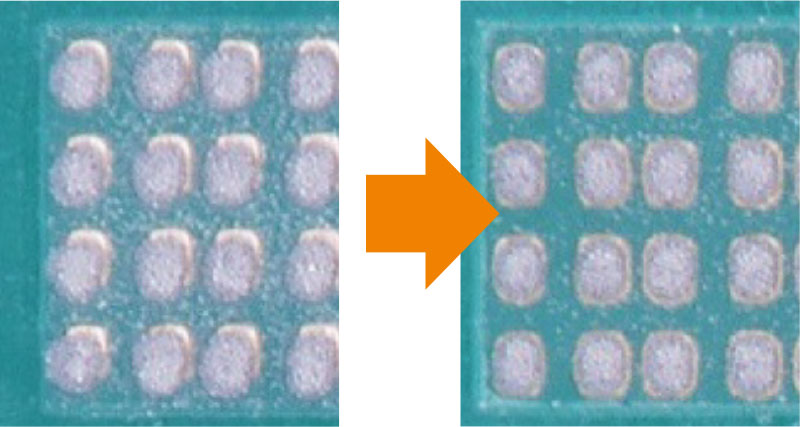

Printer's built-in inspection camera (Option)

Supports full-on pro-level inspections with a dedicated camera. Feedback from inspection results allow over-printing and stencil cleaning.

Push-up pins for high-density PCBs (Option)

Possible to arrange up to 200 pins. In addition to a 5 mm-pitched matrix plate, a 2.5 mm-pitched matrix plate with a higher degree of arrangement freedom is also available as an option.

5mm pitch specification

2.5mm pitch specification

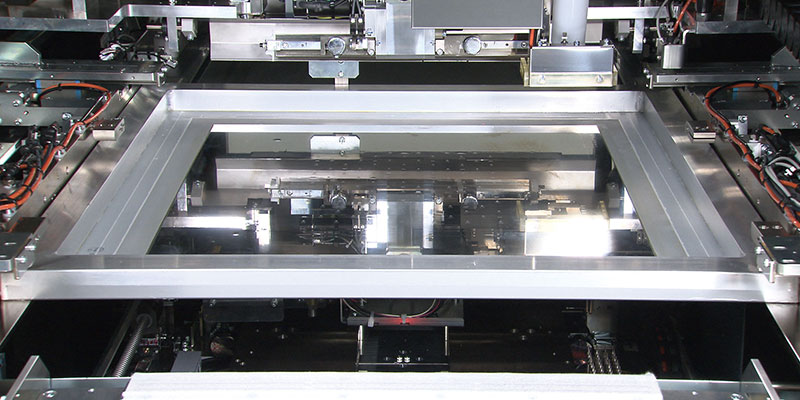

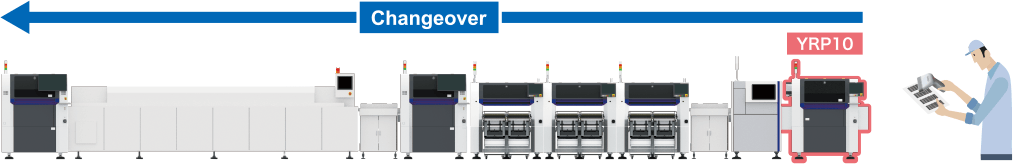

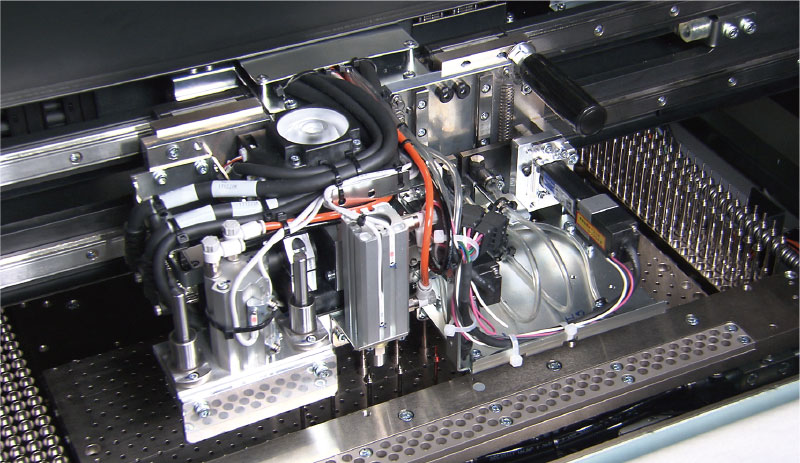

Completely automatic setups and changeovers & prolonged nonstop operation

Ultra-high-efficiency support of a variety of production models

Automatic replacement of the stencil and push-up pins. Through a combination with automatic changeovers in the entire line, man-hours and the number of human errors in model changeover have been drastically reduced. Nonstop solder supply with a 12 oz. syringe achieves prolonged, unmanned, nonstop solder printing.

Stencil replacement

- Supports multiple stencil sizes

- To be performed in parallel with push-up pin replacement

Solder transfer

- Solder rolling state is maintained

- Prevention of solder dripping from squeegee

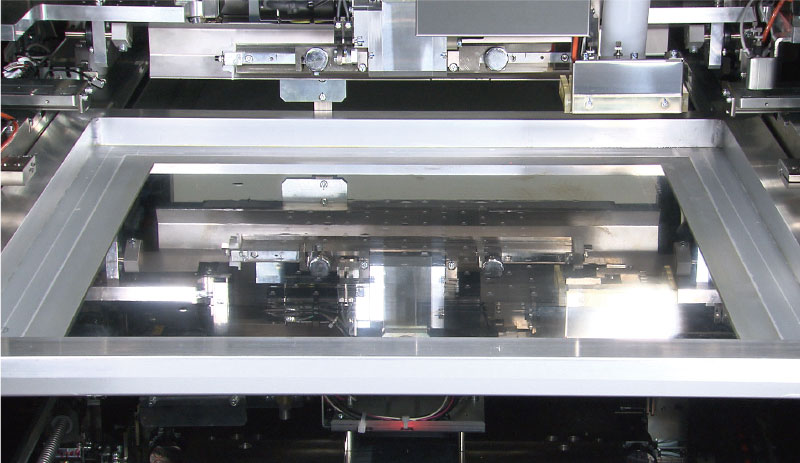

Push-up pin exchange

- Capable of handling a large PCB (L420 x W420 mm)Note

- Two-head simultaneous pickup high-speed pin replacement

- Note The 2.5mm pitch spec handles Max. L420 x W250mm PCBs.L420 x W420mm size is also available as an option.

Solder supply

- Possible to use a 6 oz. syringe and 12 oz. syringe together

- Stabilized solder rolling radius

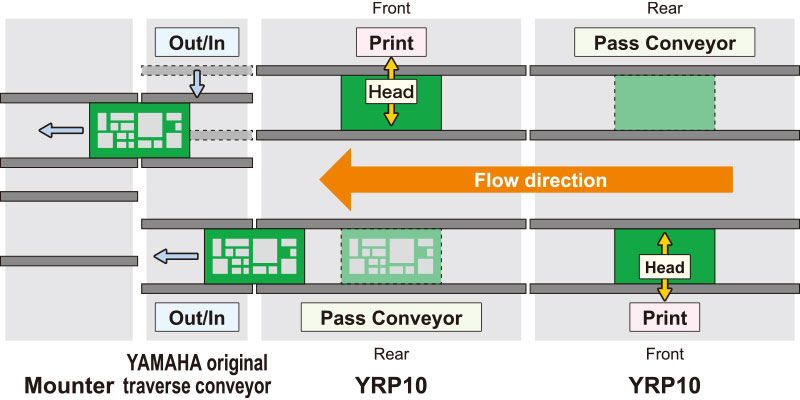

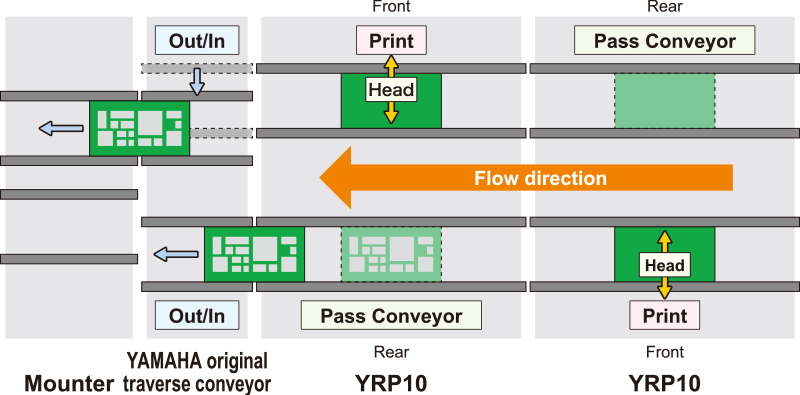

Dual lane fully independent production

Flexible dual lane

Connecting two YRP10s in series enables a fully independent dual-lane operation. A dual-lane operation and an automatic changeover feature are supported at the same time. Addition of a traverse conveyor flexibly connects the YRP10s to the downstream equipment.

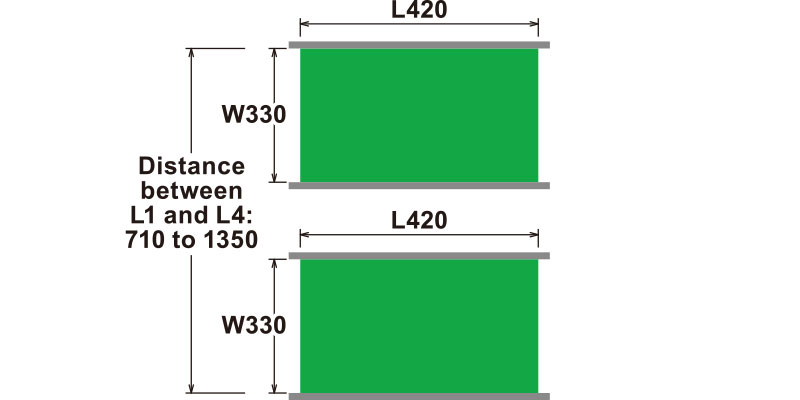

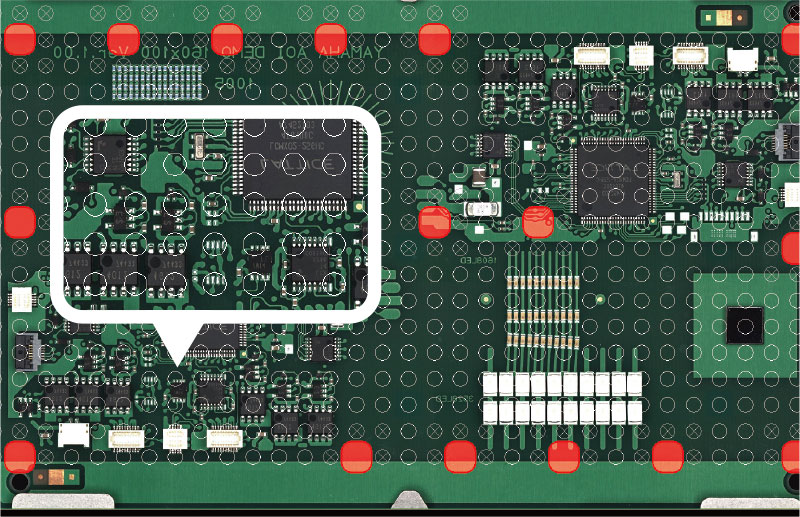

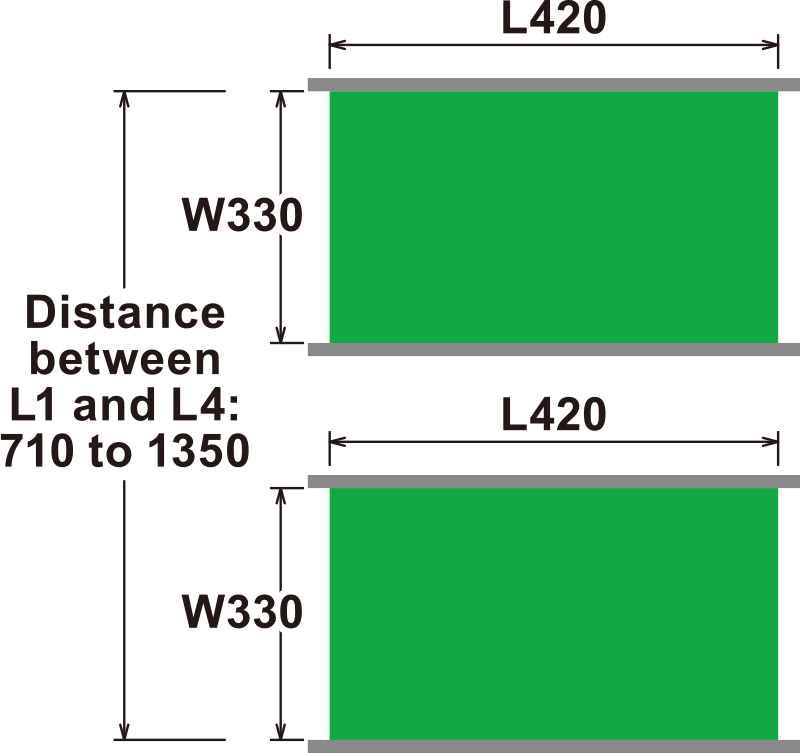

W330 dual lane

Large PCBs the size of up to L420 × W330 mm can be produced in a dual lane. You can increase the number of PCBs to take and the number of PCBs to be conveyed by the carrier, boosting production efficiency.

Dual lane

Single lane

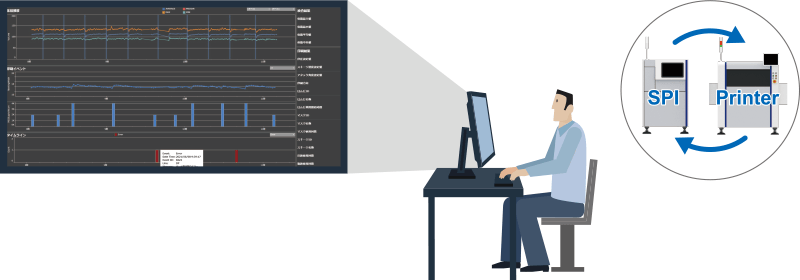

M2M link solution

Inspection result feedback

Possible to clean the stencil and correct its position using inspection result feedback via the link with the SPI.

Solder paste printing analysis

Displays link between fluctuations in solder size and solder paste printing status and allows checking the solder paste printer status when defects or problems occur. Streamline quality improvements and line operating rate.

Specifications

| Model | YRP10 |

|---|---|

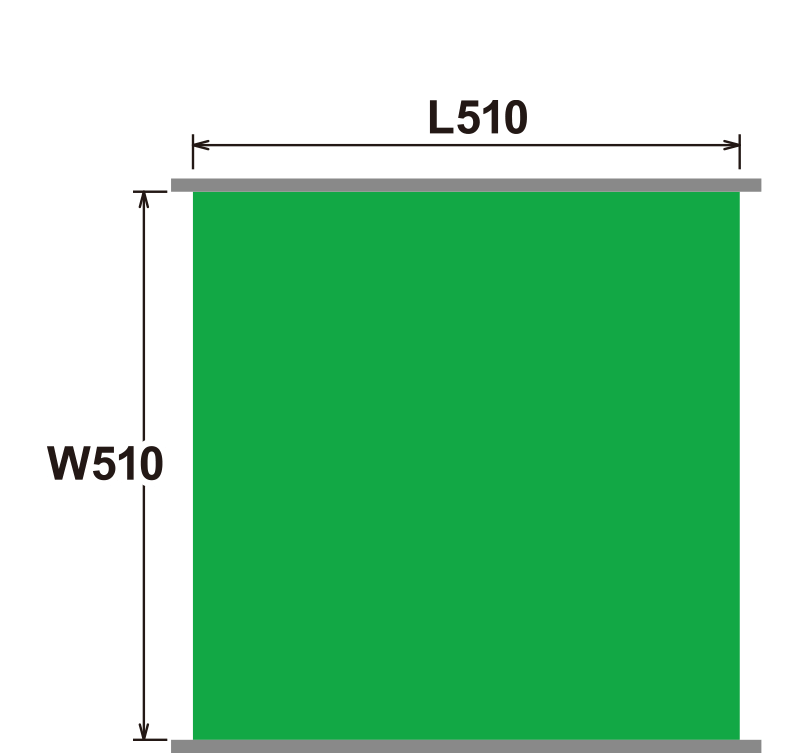

| Applicable PCB | Single lane : L510 x W510mm to L50 x W50mm

Dual lane : L420 x W330mm to L50 x W50mm |

| Printing heads | H3S head (3S : Swing Single Squeegee) |

| Printing accuracy | Positioning repeatdbility (±6σ) : ±8 μm Cp≧2.0Printing accuracy (μ±6σ) : ±16 μm Cpk≧2.0Note |

| Core cycle time(Not include printing) | 6sec |

| Applicable stencil size | L750 x W750mm, L736 x W736mm (29″), L750 x W650mm, L650 x W550mm |

| Power supply | Single-phase AC 200 to 230V +/-20V |

| Air supply source | 0.4MPa or more |

| External dimension (excluding projections) | L1,640 x W1,840 x H1,525mm (Single-lane standard specification)L3,560 x W2,300 x H1,525mm (Dual-lane specification) |

| Weight | Printer : Approx. 1,710kgTraverse conveyor : Approx. 450kg |

Note : Measured using CeTaQ under optimum conditions of YAMAHA

External dimension(Single lane)

External dimension(Dual lane)